Solinst 3001 Levelogger FAQ Frequently Asked Questions

General Levelogger Frequently Asked Questions

What is the difference between a Levelogger and Barologger?

- Leveloggers record changes in absolute pressure (water column pressure + barometric pressure) with time. The Barologger functions and communicates similarly to the Levelogger, but is used above the water level to record ambient barometric pressure in order to barometrically correct data recorded by the Leveloggers. Typically one Barologger can cover a radius of 30 km (20 miles) and/or every 300 m (1000 ft) elevation change.

- See Technical Bulletin: Barometric Compensation and the Importance of Barometric Data

What is the difference between absolute and vented (gauged) pressure sensors?

- See Technical Bulletin: Absolute Vs Vented Water Level Dataloggers – Which Method Is Right For Your Project?

How do I select the correct pressure range of Levelogger for my application?

- The choice of pressure range largely depends on the accuracy of the water level required and the desired submergence depth. The selection, however, should be based on the maximum anticipated water level fluctuation.

- Example: The Levelogger 5 M5 is designed for 5 meters or 15 feet submergence and provides a typical water level accuracy of ±3 mm (0.01 ft). This instrument is ideally suited for surface water and shallow groundwater applications, where precise water level measurements are essential.

- If, however, the anticipated water level fluctuation will be greater than the designed range, then the next available range should be chosen for that application.

- Example: 10 meters (30 feet) water level fluctuation is expected. To protect from possible over-ranging, the next available pressure range instrument (Levelogger 5 M20) should be selected.

How do I know that I'm using the most current version of software and firmware?

- The most current Levelogger software and firmware versions are available on the Solinst website Downloads page. You can check from time-to-time to see if you have the most current version, or by registering your software when you download it, you will receive automatic email messages notifying you when new software or firmware becomes available.

- In addition, when using Levelogger Software Version (4.0.1 and up) on a computer with an Internet connection, automatic notifications will be provided when new software and firmware releases are available. Clicking on the notification message will take you right to the software/firmware download page.

Do I have to pay for software and firmware?

- No, all current software and firmware versions are available to download free from the Solinst website. If you register your software when you download it, you will receive automatic notices when new software or firmware has been released.

- See Solinst Downloads page

How do I update the software?

- Download new software versions free from the Solinst website as they become available.

- See Solinst Downloads page

How do I update Levelogger firmware?

- Levelogger software comes equipped with a "Firmware Upgrade Utility". As new firmware versions become available they can be downloaded free from the Solinst website and uploaded to your Levelogger using the Utility. Ensure the software is the latest version, as it contains the most recent Firmware Upgrade Utility.

- See Solinst Downloads page

Applications

What types of applications are Leveloggers suited for?

Leveloggers are suited for the following applications:

- Long-term groundwater monitoring

- River, lake, stream gauging

- Water resource management

- Aquifer tests – pumping, slug, step, recovery

- Remote monitoring with telemetry applications

- Harbor and tidal fluctuation and wave action monitoring

- Industrial tank level monitoring

- Management of water taking/pumping

- Watershed or drainage basin recharge studies

- Wetlands and storm water runoff monitoring

- Long-term water level monitoring in wells

- Dam, reservoir, lock monitoring

- Combined Sewer Overflow (CSO) and storm water management

- Dewatering projects

- Aquifer storage and recovery observation

- Salt water intrusion and soil salination monitoring

- Plume remediation monitoring and studies

- Leachate monitoring at landfills, mine tailings, wastes disposal storage sites

- PFAS monitoring applications

- Tracer tests

- Agricultural and stormwater runoff monitoring

- And more...

Can the Levelogger be used for continuous groundwater monitoring?

- Yes, Leveloggers are self-contained dataloggers designed to continuously record water level and temperature fluctuations over time. Leveloggers are available in a number of different pressure ranges, which can be used for shallow piezometers to deep pumping well monitoring. The Solinst Levelogger software package includes features that allow you to incorporate manual water level field measurements; conduct barometric compensations; or adjust the data relative to another reference point (depth to water, ground surface elevation, etc.).

- Remote monitoring via telemetry is also an option.

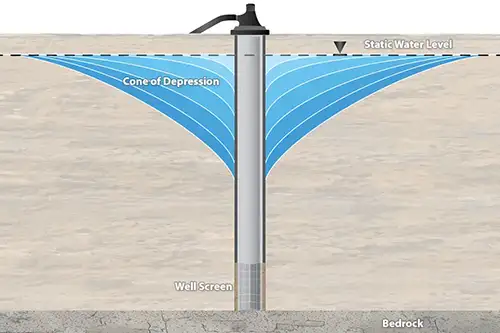

Can the Levelogger be used in pumping tests?

- Yes, Leveloggers are excellent to use during all pumping tests. The Levelogger 5 and Levelogger 5 LTC can be programmed with a customized sampling schedule that sets the rates at which water level data is collected for a number of separate intervals. You can customize different sampling rates and durations to record water level readings before, during and after the pumping test (baseline, pumping and recovery). If deployed on a direct read cable, real-time Levelogger readings can be viewed and saved on a laptop computer or smart device during the pumping test.

- See Technical Bulletin: Simplify Your Pumping Test...Use a Water Level Datalogger

Can I place a Levelogger beside an electric down hole pump?

- Yes, due to the Faraday cage design, all of the data recorded internally by the Levelogger will be unaffected from nearby electrical noise. Ideally, however, when deploying a Levelogger in a well with a pump, the Levelogger should be placed beyond any potential interference/turbulence effects from the pump's intake. If a Direct Read Cable is used, a separate insertion pipe, that is grounded, is also recommended to prevent potential electrical interference with communication when collecting or viewing data running in Real-Time mode. In the absence of a grounded insertion pipe, ensure the pump is shutoff before interfacing through the Direct Read Cable.

Are Leveloggers suited for surface water applications?

- Yes, the M5 Levelogger 5, Levelogger 5 Junior and Levelogger 5 LTC instruments utilize a highly sensitive pressure sensor for precise water level accuracy and resolution, ideally suited for surface water applications (lakes, wetland, watershed, river or stream gauging). The Levelogger 5 M5 used in tandem with a Barologger 5 can attain water level accuracies of ±8 mm/ 0.017 ft.

- Also, consider using the Solinst LevelVent 5 or AquaVent 5 vented water level dataloggers for highest accuracy in shallow water applications.

Can Leveloggers be used in saltwater environments?

- Yes, the Levelogger 5, Levelogger 5 Junior, and Levelogger 5 LTC can be used in short-term to long-term monitoring in salt water or brackish environments. The Levelogger 5 and Levelogger 5 LTC have a corrosion-resistant coating. However, in harsher environments, you can protect the Levelogger 5 Junior using a balloon filled with non-corrosive/ non-toxic fluid (tap water). As pressure changes, the fluid encasing the loggers will transmit the pressure differential to the logger's pressure transducer, without exposing it to corrosive conditions. Refer to the Levelogger Series User Guide for further maintenance recommendations.

Can I use the same Levelogger in a shallow stream and then in a deep water well?

- Yes, but as with any pressure sensor, be aware that when selecting a higher range sensor (e.g. M100) it provides less accuracy than a lower range sensor (e.g. M5). Choose a pressure range that best meets the needs of your monitoring program (without submerging beyond the calibrated range).

Can I use Solinst Leveloggers in my PFAS monitoring project?

- Yes, PFAS is not used or knowingly present in the manufacture or production of Solinst Products. The wetted materials for the Levelogger 5 are: corrosion-resistant PTFE coating baked-on using polymerization technology, acetal/Delrin® nose cone, filter and top cap, 316L SS, Hastelloy pressure sensor, and a Viton® o-ring. The Levelogger 5 LTC also includes: An acetal conductivity cell and Platinum clad Niobium core wires.

Can I use Solinst Leveloggers in groundwater with a pH of 4?

- As recommended with all our Products, before starting any environmental monitoring project, it is essential to take some steps to evaluate whether the equipment you choose will work as expected in your specific monitoring location. This means comparing the wetted materials of your Levelogger with the conditions and chemicals you expect to encounter in you monitoring project – including pH.

Installation

How deep can I install my Levelogger?

- The depth of submergence for the Levelogger (at the highest expected water level) is based on the specified pressure range for the instrument. The Levelogger 5 and Levelogger 5 LTC are available in the following pressure ranges:

Pressure Range: Maximum Submergence to Achieve Stated Accuracy: M5 5 meters (15 feet) M10 10 meters (30 feet) M20 20 meters (65 feet) M30 30 meters (100 feet) M100 100 meters (300 feet) M200 200 meters (600 feet) - The Levelogger 5 Junior is available in M5 and M10 pressure ranges.

Note: Levelogger 5 and Edge Series dataloggers can be over-pressurized 2 times (1.5 times for Gold Models) the stated submergence/calibrated range without damage to the pressure sensor, allowing for deployment flexibility.

How do I install my Levelogger in a groundwater well?

- Since Leveloggers are designed to record water level and temperature fluctuations over time (conductivity available with Levelogger 5 LTC), for successful performance in a groundwater application, they should be installed just below the lowest expected water level for that well.

- Leveloggers are installed by using either a suspension line or direct read deployment. In both deployment options the instruments are freely suspended, from the top of the well to the desired depth, via a support line (stainless steel or Kevlar cord) or a direct read communication cable. The suspension wire offers a lower-cost installation method that is ideal for shallow groundwater wells. The Direct Read Cable enables communication with the deployed Levelogger at the well head.

- See the Solinst Levelogger Deployment and Communication Guide

How do I install my Levelogger in a surface water application?

- For installations within rivers, streams, wetlands, lakes and watershed or drainage basin monitoring, the shallowest pressure range Levelogger (M5) should be considered.

- Also, consider using the Solinst LevelVent 5 or AquaVent 5 vented water level dataloggers for highest accuracy in shallow water applications.

- For direct installation in streams or rivers, stilling wells can be constructed which shield the instrument from the water turbulence. Alternatively, Leveloggers can be lowered into a protective pipe or casing and then attached to a permanent fixture such as a bridge, pier or hand driven marker/rod.

- In these types of applications, Solinst recommends that a Barologger also be used, to accurately account for barometric pressure fluctuations.

- See Technical Bulletins: Long-term Open Channel and Surface Water Monitoring with Leveloggers and Absolute Vs Vented Water Level Dataloggers – Which Method Is Right For Your Project?

How do I install my Barologger?

- The Barologger is designed to record barometric pressure fluctuations, and hence should be placed where it can capture changes in atmospheric conditions. For groundwater or surface water applications, it is recommended that the Barologger be suspended in a monitoring well or stilling well above the highest expected water level. The Barologger should be installed in a similar thermal environment to that of the Leveloggers. Typically one Barologger can cover a radius of 30 km (20 mile) and/or every 300 m (1000 ft) elevation change.

Should I use the Zero Point of the Levelogger, or measure the length of a deployed Kevlar Cord, Wire Line, or Direct Read Cable to calculate water levels?

- Accurately measuring the length of the deployment assembly/ cord, can be problematic—especially in the field, where you don't want the deployment to come in contact with the (dirty) ground surface. Also, to achieve consistent accurate measurements, you would need to ensure that you have the same amount of measured tension on each assembly. Without having a consistent amount of pulled tension, your measured accuracy will likely be much less than that of the Levelogger. Measuring deployed assemblies to determine water levels, is typically not practical, nor needed.

- Before deployment, and before each data download, Solinst recommends measuring the depth to water with a highly accurate water level meter, as well as recording the clock time. Using the Levelogger Software, you now have the ability to add all of your specific clock time "Field Zero" readings into the Data Wizard, allowing all water level readings to be accurately adjusted to that specific clock time and depth.

Monitoring

What software features are available for my monitoring needs?

- The Levelogger 5 and Levelogger 5 LTC can be programmed using Linear, Event-based, or a Customized Schedule.

- Linear: refers to a set time interval between data collection. The sample rate can be set as fast as 0.125 seconds to 99 hours. This method is commonly used for both short term and long term monitoring, respectively. The desired sampling rate is based on how much data is required in the project specifications.

- Event-based: allows the user to define a sampling interval (similar to the linear mode) however, the Levelogger will only record if the parameter value has changed by a defined threshold from the last reading. Event-based sampling can be set for specific changes in water level, temperature, or conductivity. This sampling mode is ideal for remote monitoring when only significant events are to be recorded.

- Schedule: allows you to set a number of time intervals, each with its own defined sampling rate. This sampling mode is ideal for aquifer tests (slug, pumping, recovery or step) where a fast sampling rate is used at the beginning and/or end of the test to capture the draw-down and recovery. The sampling rate can be gradually decreased over time (similar to logarithmic sampling).

Is barometric pressure important?

- Yes. All Leveloggers measure total or absolute pressure. When the Levelogger is submerged, it is recording a combination of barometric pressure + water pressure. The actual water level is obtained by removing barometric pressure effects.

- Solinst recommends the use of the Barologger in tandem with the submersible Leveloggers. The Levelogger software includes a Data Wizard, which guides the user through the automated process of barometric compensation of their data.

- See Technical Bulletin: Barometric Compensation and the Importance of Barometric Data

What if I do not have a Barologger? (How to conduct manual barometric compensations)

- When the Levelogger is submerged, it is recording the combination of barometric pressure + water pressure. Locally collected weather data can be used to barometrically correct the Levelogger data if data from an on-site Barologger is not available.

- See Technical Bulletin: Barometric Compensation and the Importance of Barometric Data

How many Barologgers do I need?

- As a rule of thumb, one Barologger for a 30 km (20 mile) radius and/or every 300 m (1000 ft) change in elevation should be sufficient to capture local variations in barometric pressure.

Should I consider the altitude or elevation of my deployed dataloggers?

- Yes. Water column equivalent pressure decreases with an increase in altitude at a rate of approximately 1.2:1000 in the lower atmosphere below 5000 m (16,400 ft). This equates to about 0.5 psi per 1000 ft increase in elevation (37 cm of water column height).

- For the Levelogger 5 and Edge Series dataloggers, compensation can be done post data collection using the Data Wizard in the Levelogger Series Software (4.5 and up).

- See Blog Post: Accounting For Altitude When Compensating Levelogger Data

Should I take manual water level measurements?

- Yes, Solinst strongly recommends that manual water level measurements be taken during the monitoring period. The Levelogger software allows the user to enter manual water level measurements to field zero the data with known values. This practice helps to ensure the accuracy of the data and also allows the user to change the datum reference point for the data set.

- If the reference datum or measuring point (e.g. top of well casing) is above water level, the field zero (measure depth to water) must be input as a positive value. If the reference datum is below water level (e.g. artesian condition), a negative value is input. The date and time of measurement of the reference datum must be recorded and input to complete the adjustment.

Levelogger Maintenance and Proper Use

- See Technical Bulletin: Ensuring Proper Use and Maintenance of Leveloggers

What if I submerge my Levelogger deeper than the specified range?

- The Levelogger 5, Levelogger 5 Junior and Levelogger 5 LTC can withstand over-pressurization of 2 times the specified range, e.g. a Model M10 can accommodate a fluctuation of 20 meters or 60 feet and still record pressure without damage. However, over-range accuracy is not guaranteed.

How long will the batteries in my Levelogger last and are they replaceable?

- The Battery life of the Levelogger 5 is 10 years, based on 1 reading per minute. Readings that are more rapid will reduce the battery life. For example, if a Levelogger 5 is programmed in Continuous Mode at a sampling rate of 1 second, the battery will be depleted in approximately 4 months. The internal batteries are factory replaceable.

- Note: The Levelogger 5 Junior has a battery life of 5 years based on 1 reading per minute and Levelogger 5 LTC has a battery life of 8 years based on 1 reading every 5 minutes.

- Drastic temperature changes beyond operating temperatures might cause battery damage or reduced battery life.

- See Technical Bulletin: Understanding Levelogger Battery Life

Is pressure recalibration necessary? When?

- Leveloggers have a lifetime factory calibration, and do not require recalibration if used in the specified range. Recalibration may be required if the Levelogger is over-pressurized by more than 2 times their intended pressure range, used in unsuitable environments, or physically damaged.

- See Technical Bulletin: Understanding Pressure Sensor Accuracy, Precision, Resolution & Drift

Is my Levelogger repairable?

- Yes, Levelogger 5 Series dataloggers are fully serviceable at Solinst. Please contact Solinst for service options and details for older generation dataloggers.

How do I protect my Levelogger from freezing?

- The operating temperature range in a liquid, for the Levelogger is between -20° to 80°C (-4° to 180°F). To avoid icing/ freezing and transducer damage, the easiest method is to lower the transducer to a point in the water column below the frost line or ice formation depth.

- In water bodies such as shallow streams, wetlands or ponds where icing/freezing may penetrate to the bottom, install the Levelogger in a vented stilling well imbedded into the bottom of the water body beyond the frost line.

- If this is not possible, place the Levelogger inside two elongated silicon, rubber or latex balloons filled with a non-toxic, non-corrosive anti-freeze solution or saltwater solution. Place the balloons in a section of perforated, 30 mm (1.25") ID pipe and install the logger in the monitored water. The antifreeze solution will protect the Levelogger from ice expansion at the pressure transducer, yet transmit any pressure and temperature fluctuations that occur.

- Note: Although precautions can be taken, placing a Levelogger in a situation where the water may freeze solid can permanently damage the sensor.

How can I protect my Levelogger from corrosive or marine environments?

- The Levelogger 5 and Levelogger 5 LTC have a corrosion-resistant coating that is baked-on using polymerization technology (inside and out). In harsher chemical environments, you can protect the Levelogger using a balloon filled with non-corrosive/non-toxic fluid (tap water). As pressure changes, the fluid encasing the logger will transmit the pressure differential to the logger's pressure transducer, without exposing it to corrosive conditions.

How can I clean my Levelogger LTC Conductivity Sensor?

- The pins of the LTC conductivity sensor are platinum-coated, therefore they should not be roughly cleaned or touched with any metal. They can be cleaned with a soft bristle brush, Q-tip, or cloth. Almost any acid solution can be selected to clean the sensor, provided it is highly diluted (generally less than 10% acid). The "soaking" time should be monitored and kept to a minimum. Refer to the Levelogger Series User Guide for further general maintenance recommendations.

Related Blog Posts

The Importance of Measuring Drawdown

How Using a Levelogger and 101D Water Level DrawDown Meter Together Provides Essential Data What is Drawdown? Drawdown is a change in groundwater level due to an applied stress, caused by events such as: Pumping from a well Pumping from a neighbouring well Intensive water taking from local area Seasonal declines as recharge rates lower How is Drawdown Measured?

Related Products

Plug and Play Telemetry

Already own Leveloggers? Quickly and easily upgrade your monitoring wells with LevelSender Telemetry. The 4G LevelSender 5 telemetry system features an optional Solinst SIM card. It is set up for you in advance—with a low-cost plan managed by Solinst! An internal barometer provides automatically compensated water level readings; set high/low level alarms.

Discover Anywhere Monitoring

SolSat 5 is a telemetry system that leverages Iridium satellite technology to provide global connectivity for Solinst 5 Series dataloggers. It uses low cost TextAnywhere global satellite messaging to send remote data to a secure web portal. It features a robust weatherproof enclosure for installation almost anywhere. Features built-in Wi-Fi setup app, solar panel, and barometer.

Solinst Readout Unit (SRU)

The Solinst Readout Unit (SRU) is a rugged, handheld device designed to connect to a deployed Solinst datalogger and display instant water level readings – with the option of automatic barometric compensation. Real-time logging and downloaded data can be saved and transferred to a PC. Quickly check the datalogger's status.

Versatile Submersible Water Level Transmitter

The 301 Water Level Temperature Sensor provides the option of highly accurate water level transmission using multiple protocols – MODBUS, SDI-12 and 4-20mA – for a wide variety of applications. This compact, all-in-one submersible hydrostatic level transmitter provides continuous, stable water level and temperature readings, with options for absolute and gauged pressure sensors.