Solinst Model 407 Bladder Pumps and Model 408 Double Valve Pumps have a lot in common.

Both are pneumatic pumps, both are excellent for providing representative groundwater samples, and both are widely used for low flow and VOC sampling.

On the outside, Solinst Bladder Pumps and Double Valve Pumps look almost identical – but internally and operationally, they are different.

The Bladder Pump has a bladder (Santoprene®) that contains the sample. It contracts and expands as pressure is applied and released from the pump.

The Double Valve Pump is essentially the Bladder Pump – but without the bladder; it relies only on valves opening and closing with pressure to bring the sample to surface.

How do these design differences determine which one you choose? Let’s discuss their operational differences.

Obtaining a Groundwater Sample

Bladder Pumps and Double Valve Pumps are pneumatic pumps, meaning an applied pressure activates them. An air compressor or a pressurized gas canister (e.g. Nitrogen gas) is used to supply the pressure to the pumps via tubing. Drive/vent cycles, where pressure is applied then released from the pump, are regulated using an Electronic Pump Control Unit.

Here’s a quick overview of how samples are collected using the pumps.

As the pumps are lowered to depth, hydrostatic pressure forces groundwater through the filter inlets. With Bladder Pumps, hydrostatic pressure fills the bladder, and sample line to static water level (the drive line remains dry). With Double Valve Pumps, the pump body, and sample and drive lines are filled to static water level, as there is no bladder to contain the sample.

During the drive cycle, gas is applied. In the Bladder Pump, this causes the bladder to slowly compress and push the sample water further up the sample line. In the Double Valve Pump, the applied pressure pushes on the water column in the drive line, which cycles the water through the pump and up the sample line. A check valve at the bottom of both pumps prevents water from exiting.

During the vent cycle, the pressure is released and new water from the formation refills the pump systems. Check valves at the top of the pumps prevent water from falling back down the sample lines. Repeated drive (pressure) and vent cycles eventually bring the sample to surface.

To best understand how a Solinst Bladder Pump or Double Valve Pump operates, we have created videos that walk you step by step through these operating principles. We also have handy operating principles documents that you can refer to whenever required. In addition, as always, Solinst technical representatives are a phone call away to answer any questions you may have, and for “live” support.

Setting the Drive of Pressure

Both Bladder Pumps and Double Valve Pumps use pressurized air or gas in drive/vent cycles to retrieve a sample (either an air compressor or pressurized gas canister is used). But, the amount of pressure required differs slightly, as outlined below.

In general, 1 psi of pressure can raise a 2.3 ft. column of water, which is about half of the column height of water in feet, expressed as psi. With Bladder Pumps, the calculation is made from ground level to the pump’s intake below ground surface. With Double Valve Pumps, this calculation is made from ground level to static water level (as a minimum, but can be made from total pump depth to maximize purging rates).

Determining the Amount of Pumping Pressure Required is Different for Bladder Pumps and Double Valve Pumps

For example, if the Bladder Pump’s intake is at 100 ft. below ground surface, you will require approximately 50 psi of pressure to squeeze the bladder enough to push a sample to ground surface. Solinst stainless steel Bladder Pumps can operate to a maximum of 500 ft. (150 m) below grade.

If a Double Valve Pump is 100 ft. below ground surface, and static water level is at 50 ft., you can select a pressure of between 25 and 50 psi. Solinst stainless steel Double Valve Pumps can lift from a maximum of 500 ft. (150 m) below static water level. As such, you can sample from greater submerged depths, compared to a Bladder Pump, as long as the static water level is maintained during pumping.

Note: both Bladder Pumps and Double Valve Pumps also come in PVC and can operate to 100 ft. (30 m).

Setting and Drive/Vent Times

Solinst has created a very helpful Sampling Groundwater document that gives you more detailed tips on setting the pumping pressure, as well as correctly setting the timers on an Electronic Pump Control Unit, to create the ideal vent/drive cycle. Tips for both Bladder Pumps and Double Valve Pumps are offered, as the approach is different for each. View that document here: http://www.solinst.com/products/groundwater-samplers/407-bladder-pumps/user-tips/pump-tips.php

Bladder Pumps have the design advantage of …well, a bladder; therefore, the sample water is never exposed to the drive gas. This makes operation more straightforward, as you are assured of an unaerated sample. It gives you more flexibility when “fine-tuning” the timers and determining the optimum drive/vent settings.

Here is a recent case study, where new users were able to quickly learn to use Bladder Pumps for their groundwater monitoring program at a landfill: http://www.solinst.com/onthelevel-news/2014/10/solinst-bladder-pumps-simplify-groundwater-sampling-ontario-landfill/

Optimizing the timers for a Double Valve Pump can be a bit trickier. The goal is to not over-pressurize so that the drive gas enters the pump and aerates the sample. Getting the drive/vent cycle correct takes a bit more finessing! Make sure you refer to our Sampling Groundwater document for all our tips. Another resource to refer to is the Solinst Technical Bulletin: Getting the Best Quality Samples from Your Double Valve Pump.

So, Which One Do You Need?

When Would I Choose a Bladder Pump?

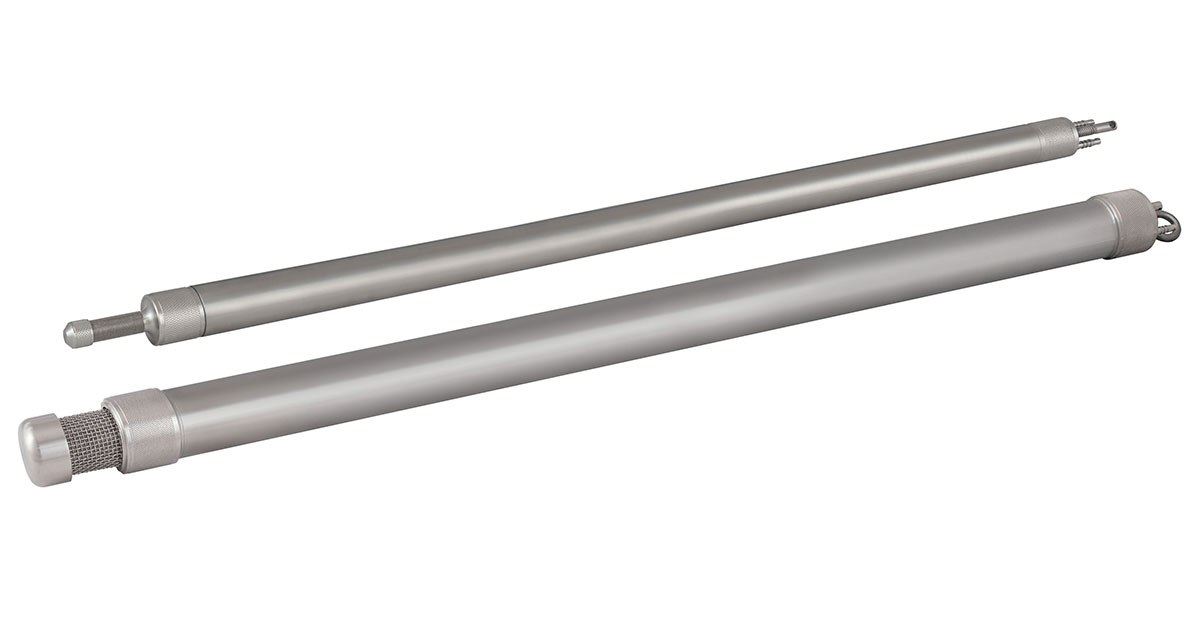

Solinst 1.66″ and 1″ Stainless Steel Bladder Pumps

If the pump is to be placed within a couple of meters below static water level, it is recommended to use a Bladder Pump. This is because Bladder Pumps only rely on drive gas compressing the bladder to retrieve a sample. A Bladder Pump can be placed just inches below static water level and still retrieve a sample.

In contrast, a Double Valve Pump relies on the drive gas pushing down on a column of water in the drive line to circulate sample water through the pump and up the sample line. The higher the water column in the drive line – the better. A larger water column makes pumping more efficient, and you are less likely to drive/push air into the pump.

You may want to select a Bladder Pump if you or your field technicians are inexperienced with pneumatic pump operation. As discussed earlier, Bladder Pumps are easier to operate because of the presence of a bladder. It is also because of the bladder, that Bladder Pumps tend to be more easily accepted by Regulators.

Regulators, and you, demand high quality, representative samples for VOC analyses; therefore, there is a preference for Bladder Pumps because there is no risk of the sample being aerated. In addition, with the slow compression of the bladder, off-gassing is minimized and turbulence is reduced during sampling.

In general, if lower flow rates are preferred, only low volumes are required, and purging of the well is not needed, then a Bladder Pump is the way to go.

Why Would I Choose a Double Valve Pump?

Solinst 1.66″ and ⅝” Stainless Steel Double Valve Pumps

Because Double Valve Pumps have no bladder to limit the sample volume, they can provide higher flow rates and faster purging. This makes them ideal when purge volumes are required prior to sampling, but high quality samples are still required for VOC analysis. Double Valve Pumps can be used for low flow sampling, and can provide high quality VOC samples when operated properly.

With the absence of the bladder, Double Valve Pumps have better performance in silty or turbid environments. They are also easier to disassemble, and have fewer parts to decontaminate. This makes Double Valve Pumps great for sampling in particulate laden groundwater.

In general, Double Valve Pumps can provide higher volume samples, more quickly, and can be used at greater submerged depths than a Bladder Pump. When operated correctly, they can provide high quality samples that are very comparable to those obtained with a Bladder Pump.

Now that you have a better idea of the differences in design, operations, and application for the Solinst Bladder Pump and Double Valve Pump, why not contact one of our technical sales representatives to further discuss your application or get a quote on the pump of your choosing?