Low Flow Sampling

Since 1996, low flow sampling has become an increasingly approved method for obtaining high quality groundwater samples. Through the work of Puls and Barcelona, the US EPA released standard operating procedures for low flow sampling (EPA/540/S-95/504). Following such guidelines ensures the collection of samples that are representative of actual in-situ conditions.

Low flow purging and sampling involves extracting groundwater at rates comparable to ambient groundwater flow (typically less than 500 ml/min), so that the drawdown of the water level is minimized, and the mixing of stagnant water with water from the screened intake area in a well is reduced.

Stabilization of parameters (pH, D.O., conductivity, temperature, etc.) and turbidity of the purged water are monitored before a sample is taken, thus low flow methods facilitate equilibrium with the surrounding formation and produce samples that are truly representative of the formation water.

Low flow methods allow the collection of high quality, representative groundwater samples in 40 ml glass vials for VOC analysis.

Automation May Not Be Best

Pneumatic gas drive pumps operated by automated pump controllers are often chosen as the desired equipment for low flow purging and sampling; however, automating these samplers may not be the best approach.

Automating the pumping rate or the drawdown is often not a good idea for wells with slow recharge. When the rate of recharge is slower than the pumping rate, an unwanted instantaneous purge can occur rather than a preferred slow and steady pumping rate that approximates the well’s recovery rate. Rapid removal of water in low hydraulic conductivity formations increases the velocity of water flowing back into a well, creating turbulence and turbidity as the well recharges.

Some automated pumping control devices stop a drive cycle as soon as the water level goes below the sensor; the drive cycle is restarted after the sensor detects water again (the well has recovered). This may lead to incomplete drive cycles and inconsistent flow rates rather than the preferred slow gentle pumping rate.

Suitable systems should allow the water to fall slowly to a maximum drawdown of less than 0.1 meter (or 1% of the standing column of water) while monitoring the entire pumping process.

In fast recovery/recharge wells, setting an automatic pump controller to maintain a minimal drawdown (less than 0.1 meter) is quite feasible. Proper drive and vent times are easy to determine and set. A Model 101D Water Level DrawDown Meter can be used in conjunction to confirm this.

Solinst Model 101D Water Level DrawDown Meter

In the end – as with any field equipment – the best practice is to have the field sampler or technician adjust the equipment to suit the pumping characteristics of each well, rather than rely on automated devices.

References

Solinst Low Flow Instruments

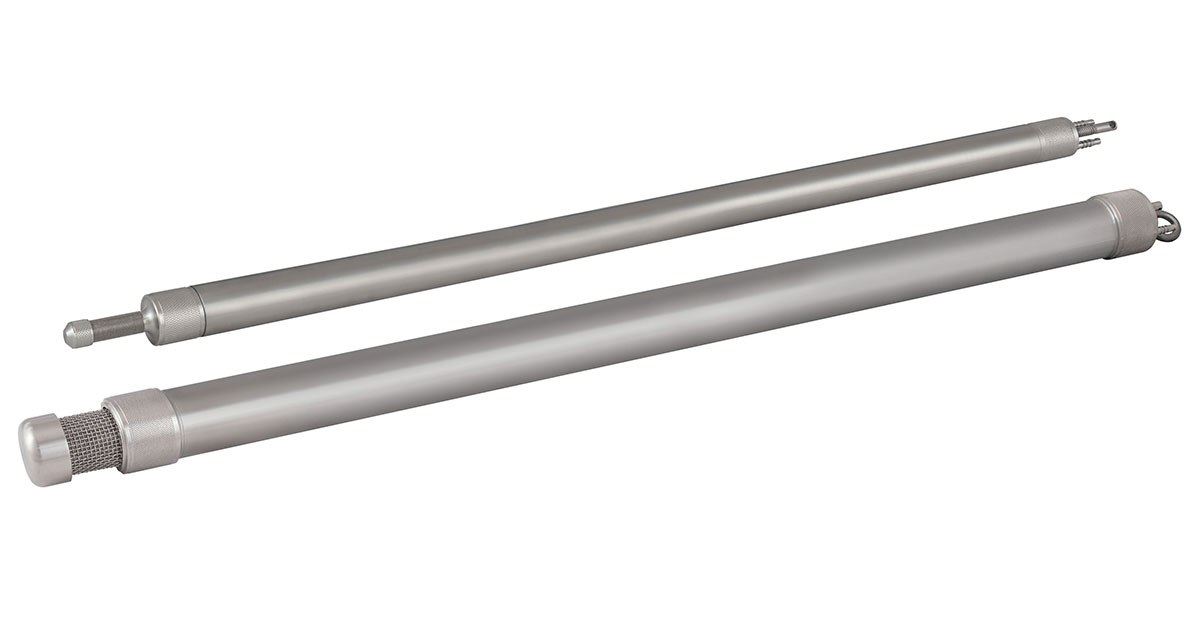

Solinst Bladder Pumps are ideal for low flow sampling. Pumps are stainless steel 1.66″ (42 mm) or 1″ (25 mm) in diameter. Bladders are available in PTFE or LDPE.

Solinst offers a variety of equipment for use in low flow applications. Double Valve Pumps and Bladder Pumps are able to provide flow rates as low as 100 ml/min, using the Solinst Electronic Pump Control Unit.

The Bladder Pump allows very slow, steady compression of the bladder during a drive cycle, unlike some other samplers, as it can be set to provide a consistent rate comparable to ambient groundwater flow. This results in representative, high quality undisturbed VOC samples. Using low flow techniques, turbulence is reduced and off-gassing minimized, providing more accurate and reliable VOC sample collection.

A submerged Levelogger water level datalogger, used with the Solinst Levelogger App or laptop, can provide viewing of real-time water level readings in the field and allows actual drawdown to be monitored during purging and sampling. Pumps can be operated manually based on the Levelogger readings.