Conductivity measurement devices have sensors that require calibration to ensure optimum performance. The frequency of calibration is largely dependent on the quality of the water it’s been exposed to during deployment.

The conductivity sensor of a Levelogger 5 LTC is highly accurate and sensitive, therefore requires regular calibration.

Levelogger 5 LTC water level, temperature and conductivity datalogger

As a minimum, calibrate your LTC Levelogger at least twice a year. Perform a conductivity calibration before its initial use, and before any subsequent monitoring project—especially after prolonged periods of storage.

Check out our step-by-step video showing a 2-point conductivity calibration!

A quick way to find out if your Levelogger 5 LTC needs to be recalibrated is to test it in a solution with a known electrical conductivity and reference temperature. Using the Real Time View function in the Levelogger Software, observe live conductivity readings.

If you find that your conductivity readings are outside the stated accuracy range, you can perform a user Levelogger 5 LTC calibration to get it ready for the field again.

Here are five tips to help ensure your Levelogger 5 LTC calibration is successful, resulting in accurate conductivity readings.

1. Make sure you have the latest Levelogger Software.

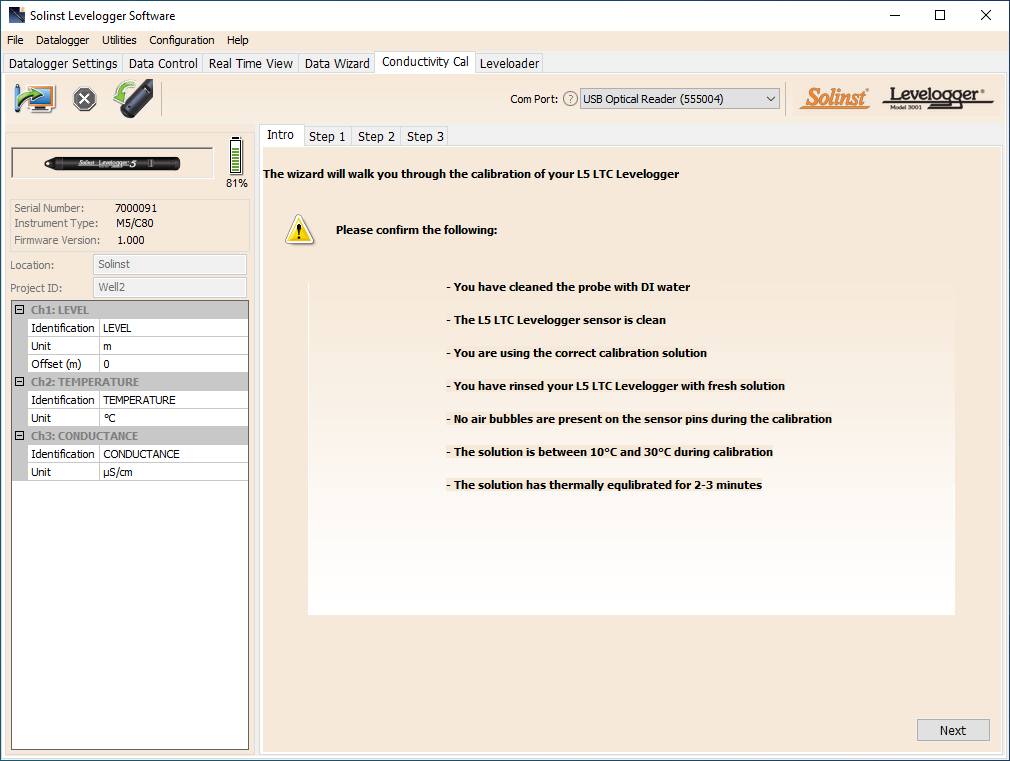

To calibrate an Levelogger 5 LTC, you require Levelogger PC Software; it includes the easy-to-follow Conductivity Calibration Wizard.

Levelogger Software Conductivity Calibration Wizard

The Levelogger 5 LTC is compatible with Levelogger Software version 4.5 and up. Solinst always recommends using the latest software and firmware versions to ensure compatibility.

In our blog post, Levelogger Compatibility Explained – Ensuring Proper Hardware, Firmware & Software, we tell you how to find out if you need a firmware or software update, and if required, the steps to make sure you do it properly.

To perform an Levelogger 5 LTC calibration, you will need to connect it to the PC using an Optical Reader (Desktop Reader 5 or Field Reader 5). You may need to verify the USB driver for this device has been installed to work with your computer. We provide detailed instructions for USB driver installation in our Levelogger User Guide.

2. Keep the Levelogger 5 LTC conductivity sensor clean.

The Levelogger 5 LTC conductivity sensor will not calibrate properly if it isn’t clean.

You should clean the conductivity cell and sensor pins thoroughly before calibration, and rinse in between each step/solution when doing a multipoint calibration.

The pins of the LTC Levelogger sensor are platinum-coated, so they should not be roughly cleaned or touched with any metal. They can be cleaned with a soft bristle brush or Q-tip, or cloth.

Cleaning a Levelogger 5 LTC Sensor

Almost any acid solution can be used to clean the conductivity cell and sensor pins, provided it is highly diluted (generally less than 10% acid). For stubborn hard water deposits, etc., the Levelogger 5 LTC can be soaked in this diluted acid solution, but time should be monitored and kept to a minimum.

Always rinse with deionized water after cleaning and before you start calibration.

When you are performing a multipoint calibration, rinse the Levelogger 5 LTC with deionized water between each step, and then rinse with the next solution you will be using.

3. Select the appropriate calibration solutions.

To start, you have to use the specified conductivity solutions: 1413, 5000, 12,880, or 80,000 µS/cm. If you don’t, you’ll get errors during the Levelogger 5 LTC calibration process.

(Note the previous LTC Levelogger Junior model can only be calibrated to 3 points: 1413, 5000, 12,880 µS/cm.)

The calibration solutions should be fresh. It’s better to use ones that have a temperature error of ±2% or better.

For best conductivity calibration, we recommend you use a 2-point calibration with solutions closest to what you expect to find in the field. For example, use 1413 and 5000 µS/cm solutions if you are expecting to encounter conductivities between those values during the monitoring period.

If you are measuring in water less than 1,413 μS/cm or above 80,000 μS/cm, you can use just a single calibration solution.

But, it’s all up to you; you can perform a 1, 2, 3, or 4-point calibration.

4. Get rid of the bubbles before calibrating.

When immersed in solution, the Levelogger 5 LTC conductivity sensor is designed to avoid bubbles from forming, but just in case…

Tap, stir and shake your Levelogger 5 LTC.

You want to ensure there are no air bubbles on the conductivity sensor before calibrating in a solution. Air bubbles will result in an inaccurate or failed calibration.

Stir and lightly tap the Levelogger 5 LTC in solution to remove the bubbles—this should only take a few seconds. It is helpful to use a clear container for calibration, so that you can see the bubbles leaving the sensor.

After stirring, allow the sensor to stabilize and thermally equilibrate. Waiting for the sensor to properly equilibrate can take from 30 seconds up to a few minutes.

Levelogger 5 LTC Stabilizing in Calibration Solution

5. Maintain temperatures throughout calibration.

The deionized water, calibration solutions, and conductivity sensor should all be at similar temperatures—and should be maintained throughout the Levelogger 5 LTC calibration.

During calibration, the solutions should be kept as close as possible to the manufacturer’s stated temperature (usually 25ºC).

Generally, you should keep the solution between 10 and 30ºC for best accuracy. If outside that range, the Levelogger 5 LTC may not pass calibration. Solution temperature should be kept stable throughout the calibration.

Hint: Use the Real Time View feature to check the temperature the Levelogger 5 LTC is recording in the solution, to verify that the LTC and solution have stabilized before calibration.

A Successful Levelogger 5 LTC Calibration

Take these 5 tips, carefully follow the calibration instructions in the Levelogger User Guide and Conductivity Calibration Wizard, and you’ll get an accurately calibrated Levelogger 5 LTC every time.