Accuracy, Precision & Resolution

Accuracy, resolution, and precision are often interchanged when discussing the specifications of a pressure sensor. Here, we will differentiate between the three in relation to Solinst Levelogger, LevelVent, and AquaVent datalogger pressure sensors.

Pressure Sensor Accuracy

Accuracy is how closely the measured value reported by the pressure sensor comes to the actual pressure. It is stated as the difference between the two values, expressed as a percent of the sensor’s full scale (FS).

For example, if the Levelogger 5 M100 with a full scale of 100 m reports a pressure of 88.0500 m, and the actual pressure is 88.0000 m, then the difference is 0.0500 m (5 cm); divide 0.0500 m by 100 m and express as a percentage – accuracy (or error) is 0.05%. The Solinst Levelogger 5, LevelVent 5, and AquaVent 5 have an accuracy of ±0.05% FS.

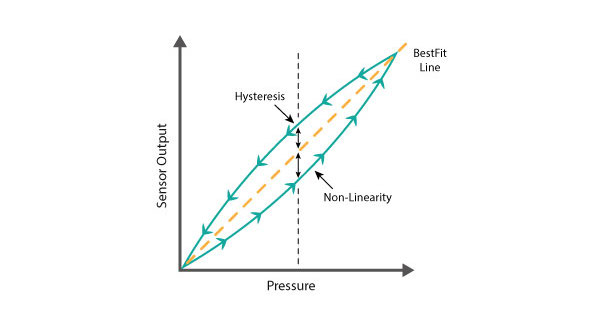

An accurate pressure sensor must also limit non-linearity and hysteresis. Non-linearity is the deviation of the sensors output from a specified best fit straight line over the full scale. Hysteresis is the maximum difference in the value of the readings at a specific point, one reading is obtained while increasing the pressure and the other while decreasing from full scale.

The Solinst datalogger calibration procedure ensures linearity and hysteresis specifications are met. During the calibration procedure, the datalogger is fully submerged in a highly accurate water bath. The bath is allowed to stabilize. The pressure is then calibrated to six separate pressure points covering the entire range of pressure to check for any non-linearity and hysteresis (the procedure is repeated at two more temperatures).

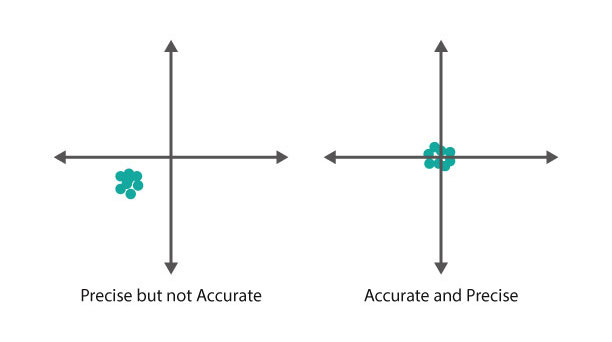

Pressure Sensor Precision

Precision is how close all the sensor readings are grouped to each other – a more precise sensor has a narrow distribution of readings at a given pressure. In other words, a precise pressure transducer produces consistently repeatable measurements.

Solinst datalogger pressure sensors are precise with superior stability and low noise.

Pressure Sensor Resolution

Resolution is the smallest degree of pressure change that can be detected and recorded by the pressure sensor.

For example, the Levelogger 5 M100 has a resolution of 0.0006% FS. This means with a full scale of 100 m, the sensor will be able to detect a 0.0006 m (0.6 mm) change in pressure. Resolution usually varies over the range of the instruments, e.g. the Levelogger 5 M5 has a resolution of 0.001% FS

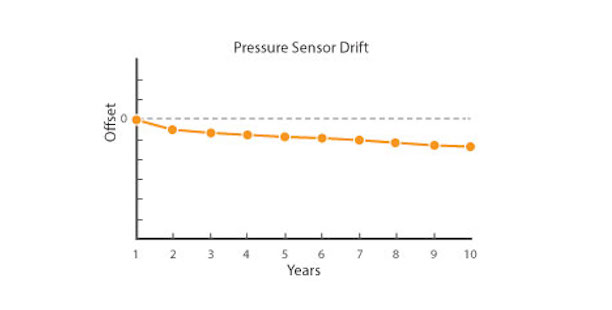

Pressure Sensor Drift

All pressure transducers – no matter what they are made of, how expensive they are, or how accurate – are susceptible to sensor drift over time. Pressure sensor drift is a gradual degradation of the sensor and other components that can make readings offset from the original calibrated state.

Based on their intended application, sensors are engineered from various materials. When exposed to certain conditions, the sensors will respond differently depending on the physical properties of the materials chosen.

Every sensor will undergo some expansion and contraction when subject to pressure and temperature cycles. Pressure change frequency and amplitude, temperature extremes, material responses and environmental changes are all factors contributing to drift. The magnitude a sensor will drift varies with actual usage and the conditions it is exposed to.

Pressure Sensor Calibration

It is important to note that manufacturers test and calibrate their sensors in closed environments to achieve desired specifications and a zero point. Some manufacturers provide a value for the expected drift or long term stability, but these numbers are still based on use in very stable environments, making them somewhat irrelevant in normal use.

Solinst Pressure Sensors

Solinst Leveloggers are water level dataloggers that use an absolute pressure sensor to detect the depth (or pressure) of water above the logger. For the Levelogger 5, Solinst chose to use a Hastelloy pressure sensor because of durability, long term stability, accuracy, and corrosion resistance. LevelVent 5 and AquaVent 5 water level dataloggers also use a Hastelloy pressure sensor, but it is vented to the atmosphere.

Hastelloy pressure sensors are more tolerant when it comes to being over-pressurized. Other sensors, such as ceramic sensors, tend to be more brittle and can shatter when they experience over-pressurization, ice accumulation, or water hammer effects.

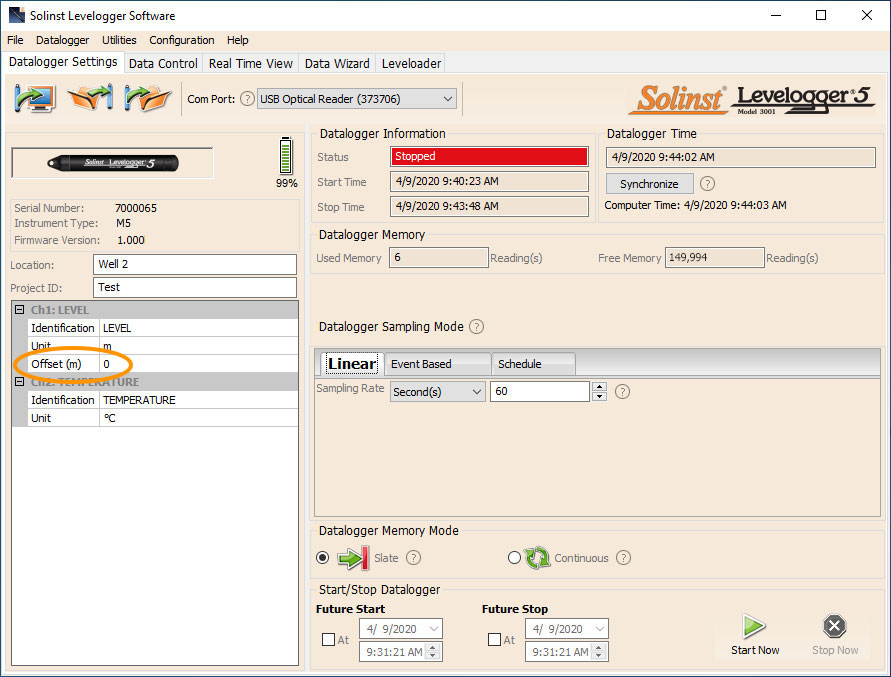

The Model 3001 Levelogger 5 is an accurate water level and temperature datalogger that provides a compact method of recording uninterrupted, long-term data. The Levelogger 5 consists of an absolute pressure sensor, temperature thermistor, datalogger and 10-year lithium battery, in a stainless steel housing with a PFAS-free corrosion-resistant coating inside and out. A memory for 150,000 sets of readings allows higher-resolution data with more frequent readings. Accuracy is 0.05% FS.

Get a Quote!

Correcting for Drift

Factory re-calibration can be attempted to correct for drift, but may not be required. Regular “field zero readings” will serve to eliminate the effects of drift on pressure sensor readings.

The best recommendation is to compare barometrically compensated Levelogger data (or raw LevelVent and AquaVent data) with a manually measured water level value (depth to water using a Model 101 Water Level Meter, 101D Water Level DrawDown Meter, or 102 Water Level Meter, or a staff gauge depending on your application).

By routinely taking manual water level measurements, and comparing these readings to those recorded by the datalogger at the same time, an offset value can be determined. This offset value can then be used to correct future datalogger readings.

For example, If using a depth to water measurement for comparison, the deployment depth of the Levelogger, minus the manual depth to water measurement, should equal the compensated Levelogger reading. If not, the difference between the two readings is the offset value, or calculated sensor drift.