Solinst Eureka, a global leader in the design and manufacture of multiparameter water quality sondes.

Safeguard your project’s success and mitigate any potential for downtime or additional costs.

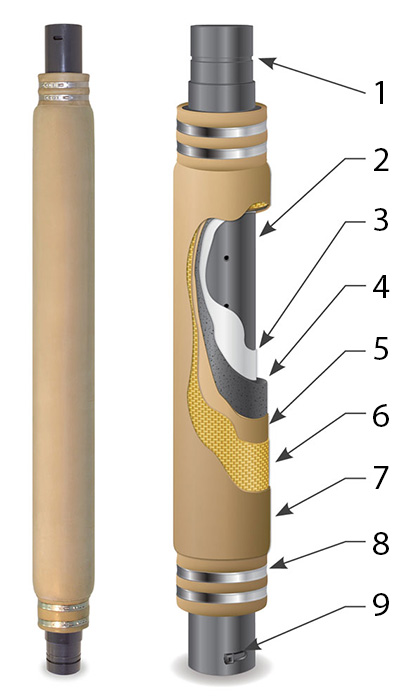

Permanent Packer for Waterloo Multilevel System

Permanent packers ensure long term integrity of seals in cored bedrock holes and cased wells. They use a water activated expansion sleeve fitted over the perforated packer body. A layer of porous plastic distributes water evenly to the packer expansion material. A Rubber/Kevlar/Rubber sheath envelops the expansion material. The Kevlar layer provides strength to bridge across large fissures. The pliant gum rubber forms an effective seal against the borehole wall.

Water is added to the inside of the sealed casing string after installation. The water passes through the packer body into the expansion sleeve, causing the material to expand. Thus an engineered seal is permanently formed against the borehole wall.