The answer is yes – especially if you use a Solinst CMT Multilevel Groundwater Monitoring System. CMT Systems are low cost, quickly installed, and are easily customized to suit your multilevel groundwater and soil gas monitoring needs.

What is CMT?

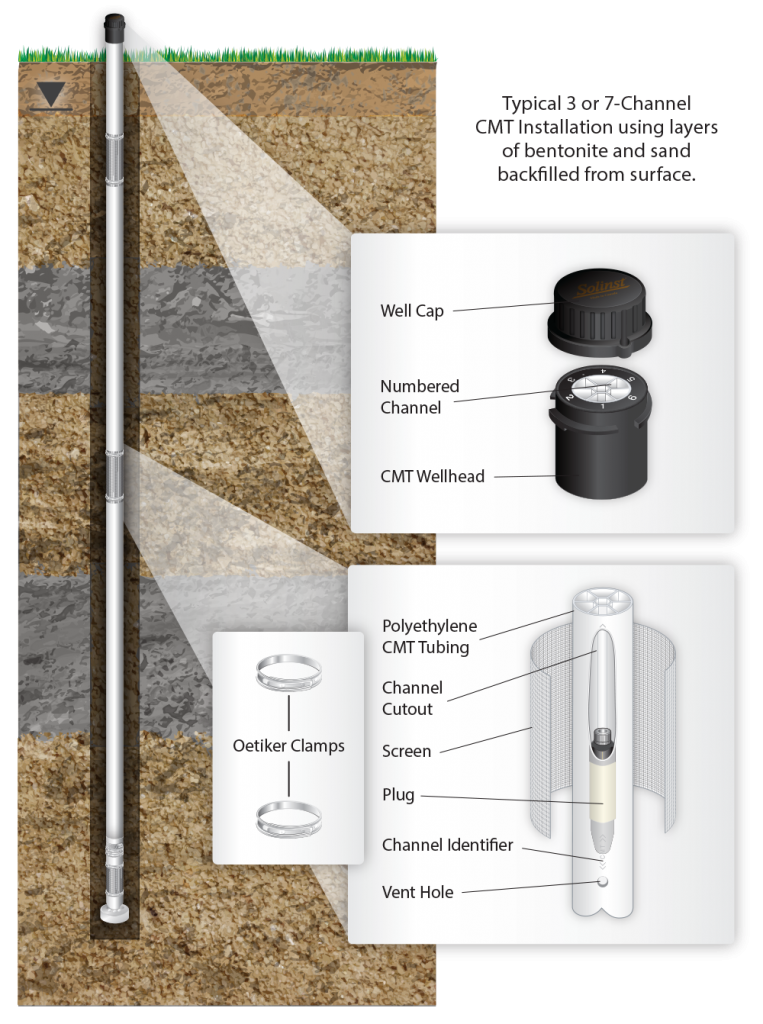

CMT stands for Continuous Multichannel Tubing. CMT is continuously extruded medium-density polyethylene (MDPE) tubing that has seven or three separate channels running through its entire length. CMT is supplied in continuous lengths up to 300 ft. (seven-channel) or 500 ft. (three-channel), with no joints.

Here are some illustrations to help with this description:

The seven-channel tubing is 1.7″ in diameter, while the three-channel tubing is only 1.1″ in diameter. Each channel can fit 3/8″ diameter monitoring equipment, allowing the insertion of narrow water level measurement devices or groundwater sampling pumps.

So, how does this tubing become a complete multilevel groundwater monitoring system?

Monitoring ports are manually created using hand tools and sealed off using plugs and stainless steel screens. One monitoring port can be constructed for each tubing channel. This means that you can design your CMT Groundwater Monitoring System to monitor up to seven discrete zones in one well, with each zone monitoring a different depth.

As discussed in a previous blog post, multilevel groundwater monitoring systems, often referred to as engineered nested wells, provide high-resolution subsurface data and have many advantages when compared to traditional monitoring wells, such as clustered and nested wells. Watch a video that shows the differences between conventional long-screen wells and multilevel wells on our YouTube channel.

How do you construct CMT monitoring ports?

Solinst has developed a video that walks you step-by-step through the construction of the monitoring ports for a CMT Multilevel Groundwater Monitoring System.

The video shows how to use the Port Cutting Guide; a unique tool that is designed specifically for creating the CMT port openings, and at the same time, ensuring you construct your ports in the proper channels. In addition, it shows how the tubing has a convenient “CMT” identifier along the length of Channel 1, so you know which channel to start with.

The monitoring ports can be constructed anywhere along the tubing. This provides the flexibility to adapt the CMT System to your specific borehole logs. Often, the CMT ports are constructed right on site where the drilling is taking place. With practice, two people can assemble a seven-channel system, in less than two hours.

How are CMT Multilevel Groundwater Monitoring Systems installed?

CMT Multilevel Groundwater Monitoring Systems are smooth, single tubes with no joints (and no packers, if desired) to worry about during installation. They can be installed in boreholes and finished with sand and bentonite backfill layers or natural formation collapse.

The narrow three-channel systems can be installed using special sand and bentonite packers, which are designed to work with direct push rigs and seal NQ core holes.

Typical 3 or 7-Channel CMT Installation Using Layers of Bentonite and Sand Backfilled from Surface and a Typical 3-Channel Installation in Overburden with Bentonite and Sand Cartridges

Various drilling methods and techniques have been successful for installing CMT wells; check out our summary of methods that have been used in unconsolidated aquifers.

Do you want to become a Trained CMT Contractor?

As the push to clean up contaminated sites continues, the need for high-resolution subsurface data is growing – so too is the opportunity for those offering environmental drilling services.

Solinst offers a training program to environmental drilling contractors to be recognized as “Trained CMT Contractors”.

The training program includes both instruction and hands-on demonstration for CMT construction and installation. Attendees learn proper handling, assembly, installation and monitoring techniques. In addition to drilling contractors, regulators and consultants often attend training sessions.

Solinst holds training sessions at our headquarters in Georgetown, Ontario Canada, as well as at conference and trade show events; Solinst staff also travel to drillers’ facilities to provide instruction. In some states, these training courses can qualify for continuing education credits.

To date, over 150 environmental drilling contractors have gone through the CMT training program. “Trained CMT Contractors” are listed on the Solinst website at: http://www.solinst.com/Prod/403/training.html

Please contact Solinst should you wish to attend or set up a training session. You’ll see just how easy multilevel groundwater monitoring can be.

Is CMT widely accepted?

In a word – yes. Since its inception in 1999, our recent estimation is that over 5,000 installations have been completed worldwide.

Since the CMT is a simple and inexpensive solution to multilevel groundwater monitoring, the numbers are sure to continue upwards.

Think the CMT is what you need for your subsuface investigation? Get a Quote!