モデル405リバース・ヘッド・プロフィール

水質プローブ

ソリンスト・ユーリカ社は、マルチパラメーター水質ゾンデの設計・製造における世界的リーダーである。

ソリンスト・フィールド・サービス

プロジェクトの成功を守り、ダウンタイムや追加コストの可能性を軽減します。

リバース・ヘッド・プロフィール

リバースヘッドプロファイルは、ソリンスト・フルート社が開発した技術で、フルート透過率プロファイルの終了後に、孔内の鉛直ヘッド分布を測定するためのものです。

リバース・ヘッド・プロファイルはどのように機能するのか?

この方法では、透過率プロファイルの完了後、段階的にブランクライナーを反転(除去)する。ブランクライナーは、透過率プロファイルによって特定された関心のあるフローゾーンの間で停止されます。

ブランクライナーが坑井から反転されると、透過率プロファイル中に密閉された、関心のある個別のボアホール区間が露出します。ボアホールのライナーの下に設置された圧力変換器が、各区間が露出した後の新しい定常状態のボアホール平衡圧力Bhiを記録します。各区間の透水係数と以前の定常状態の孔内平衡圧がすでに分かっているので、ライナーの下にある新しい「混合ヘッド」をそれぞれ使用し、覆いが外された各増分の流量方程式を書くことによって、新たに覆いが外された孔内区間の寄与を計算することができます。

孔内への純流入と孔外への純流出をゼロと定義し、孔内の各増分で測定された透過率Tiを用いて、孔内の新たに露出した各区間の地層ヘッドFHのみを未知数とする。

ライナー下の最初の開孔区間:

T1(Bh1-FH1) = 0

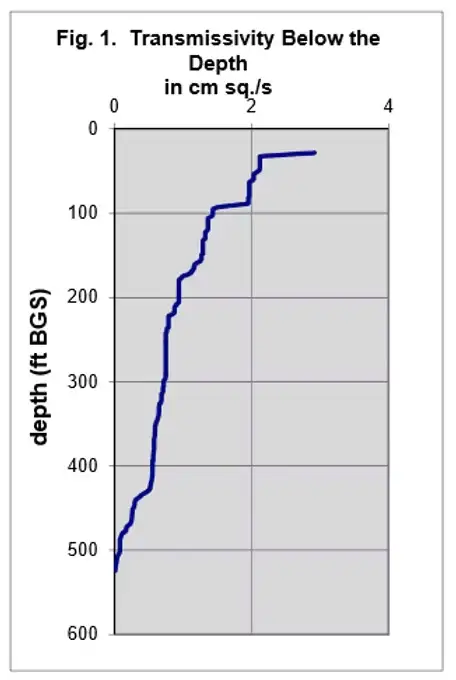

したがって、フォーメーションヘッドFH1は、ブレンドヘッドBh1に等しい、 を計算した。各区間の透過率Tiは次のように求められる。 連続透過率積分から(図1)。

ライナーを反転させ、ボアホールの2番目のインクリメントを明らかにする:

T1(Bh2-FH1) + T2(Bh2-FH2) = 0

FH2を解く、

FH2= [ T1(Bh2-FH1)+ T2 Bh2 ]/T2

注:

新しいポジションごとに、新しいブレンドヘッドBhiが測定される。

ライナーを反転させるたびに地層の揚程を解くことで、透過率の測定と孔の密閉に使用したライナーを取り外しながら、地層の揚程分布を理論的に求めることができます。

現在の区間iのフォーメーションヘッドの解の方程式は次のようになる:

FHi = [ T1(Bhi-FH1) + T2(Bhi-FH2) + …… +Ti Bhi ]/Ti

ここで、Tiはライナーの連続透過率プロファイルから決定された孔内のi番目の区間の透過率、FHiは計算されたi番目の区間の地層水頭、Bhiは新しいi番目の区間が掘削されるたびに孔内で測定される混合水頭である。ライナーの下でのトランスデューサーの測定値を見ることで、ライナーの下で定常状態に達した揚程を判断することができます。

リバース・ヘッド・プロフィール結果

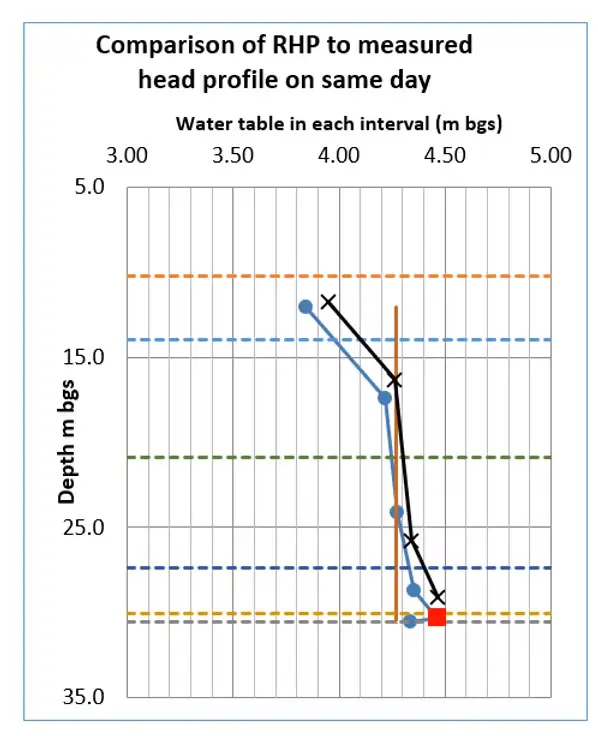

図2.30mボーリング孔で実施した2つの逆揚程プロファイル。青い点は1回目のRHPの値から測定したもので、黒い点は2回目のRHPで測定したものです。垂直の赤い線はボーリング孔内の元の混合水頭であり、BGS30メートル地点の赤いプロット点は非常に低い透過性ゾーンで測定されたものであるため、信頼性の低い水頭計算であることに注意してください。

関連商品

強化されたバイオレメディエーション

について ウォータールー エミッター は、汚染された地下水のバイオレメディエーション用に設計された、シンプルで低コストの装置です。酸素やその他の添加剤を、制御された均一な方法でシリコンまたはLDPEチューブを通して拡散させることができます。MTBEやBTEXの好気性バイオレメディエーションに最適で、メンテナンスは最小限で済みます。

3/8インチ径フレキシブル空圧ポンプ

について マイクロダブルバルブポンプ は、驚くほど小型でフレキシブルな設計です。直径3/8インチ(10mm)で、CMTシステムのチャンネルから地下水をサンプリングするのに十分な大きさです。

堅牢なペリスタポンプ

小型、軽量、耐水性のソリンスト蠕動ポンプは、現場での使用に適しています。簡単にアクセスできる1つのコントロールで、様々な速度と可逆流が可能。浅い水や蒸気のサンプリングに最適。

キャッチフレーズ – 堅牢、シンプル、便利

について タグ・ライン 頑丈なリールに取り付けられたレーザーマーク付きケーブルに重りを取り付けて使用。モニタリング井戸建設時の深度測定に便利。