Importance of Multilevel Subsurface Monitoring

Depth Discrete Groundwater Monitoring

Reduce Costs and Field Time

The Importance of Multilevel Subsurface Monitoring

Multilevel groundwater monitoring involves creating a series of discrete, isolated intervals at various depths within a single borehole. This high-resolution subsurface profiling method offers several advantages:

- Detailed Subsurface Data: provides comprehensive data for accurate 3D site assessments, including both horizontal and vertical contaminant concentrations and flow patterns.

- Overcoming Long Screen Issues: short multilevel screens address problems associated with long screens, which can mix groundwater chemistry over their entire length.

- Preventing Cross-Contamination: properly isolated multilevel monitoring prevents ambient flow between different zones within a well, thereby avoiding crosscontamination or flow outside the well.

- Cost-Effectiveness: a multilevel well is a cost-effective alternative to installing multiple boreholes. It reduces site disturbance, minimizes the number of required permits, and

shortens on-site time. - Efficiency in Field Operations: reduces field time due to smaller purge volumes, more efficient sampling, and rapid response to pressure changes in small-diameter monitoring

tubes. This leads to less waste disposal and a more streamlined process. - Improved Remediation Strategies: enhances remediation strategies by allowing for the monitoring of plume thickness, concentration variations, movement, and extent of a plume

over time.

Solinst Multilevel Groundwater Monitoring Systems

In addition to the Water Flute, Solinst Manufactures three other multilevel systems, each suited to different environments and applications.

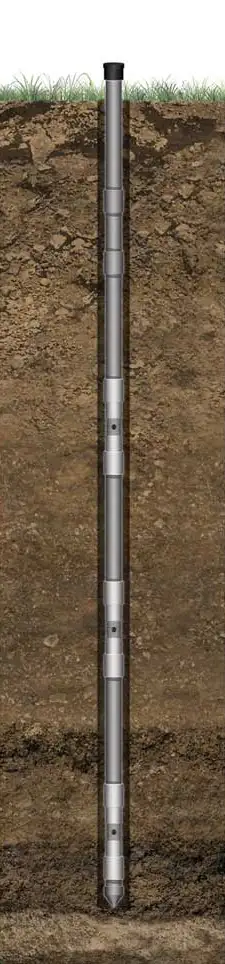

615ML Multilevel

Drive-Point Piezometer

The 615ML Multilevel Drive-Point Piezometer has stainless steel monitoring ports connected using 3/4″ NPT steel drive pipe and couplings. Dual barb stems allow the connection tubing to create up to 3 or 6 monitoring zones, depending on tubing size. Drive-Point Multilevel Systems can be installed simply using direct push methods, including a manual slide hammer. These systems are easy to transport with portable sampling and level monitoring options (see Model 615ML Multilevel Drive Point Piezometer Data Sheet).

403 CMT®

Multilevel System

The 403 CMT® Multilevel System consists of continuously extruded polyethylene tubing with seven or three separate channels running its length. Monitoring zones are mechanically created and sealed off, one in each separate channel at different vertical intervals. CMT offers in-field design flexibility, is low cost and easy to install. The 7-Channel System is 1.7” (43 mm) and the 3-Channel is 1.1” (28 mm). They are ideal for shallow applications in narrow diameter boreholes (see Model 403 CMT Multilevel System Data Sheet).

401 Waterloo

Multilevel System

The 401 Waterloo Multilevel System uses modular components of various casing lengths, sampling ports, and optional packers that are connected to form a sealed casing string. Pumps and/or transducers can be dedicated to each port. All instrument tubing and cabling is contained within these modules and collected at the top of the system at a wellhead manifold. The Waterloo System is ideal for long-term monitoring in bedrock and cased boreholes, and has been used to depths of 1000 ft. (300 m) (see Model 401 Waterloo Multilevel System Data Sheet).