Solinst Eureka, a global leader in the design and manufacture of multiparameter water quality sondes.

Safeguard your project’s success and mitigate any potential for downtime or additional costs.

Flute liners are flexible sleeves of impermeable nylon fabric that are closed on one end. When installed in a well and pressurized with air, water, or mud, the liners seal to the interior of a borehole.

Flute liners can be made of very thin nylon to ballistic strength 840 denier nylon in diameters ranging from 2” to 19″+ (50 mm to 48 cm+).

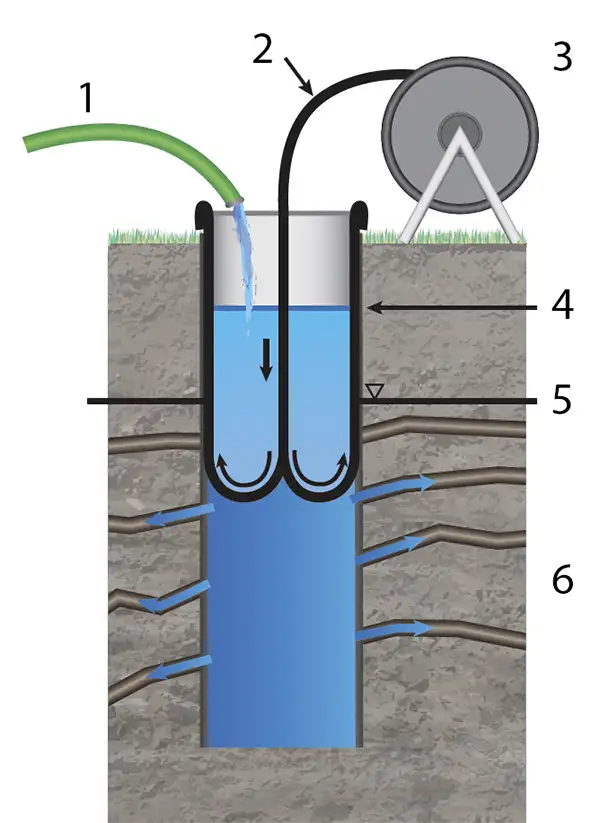

The end of the liner is pulled off of the shipping reel and folded inside out forming an annular pocket. This annular pocket is then lowered down inside the casing and secured at the surface. Water is then added to the pocket to a level above the water table in the formation, creating the driving pressure necessary to start the eversion process.

The driving pressure (typically 5 to 10 feet of water pressure) allows the liner to propagate down the borehole (eversion), displacing the borehole water into open flow paths and seals the liner firmly to the borehole wall. See the Model 405 Blank Liner Data Sheet to learn more about the importance of sealing a borehole.