CMT Specifications & Considerations

7 Channel CMT System

3 Channel CMT System

Note:

* Tubing is MDPE; proprietary mix of HDPE and LDPE products.

** Avoid using ‘single lifts’ of grout, greater than 50 ft in the unsaturated zone.

*** Each CMT coil measures 1 to 2 ft longer than stated.

**** If air temperature is above +35ºC, use cold water to cool down the tubing at the port before installing the port plug.

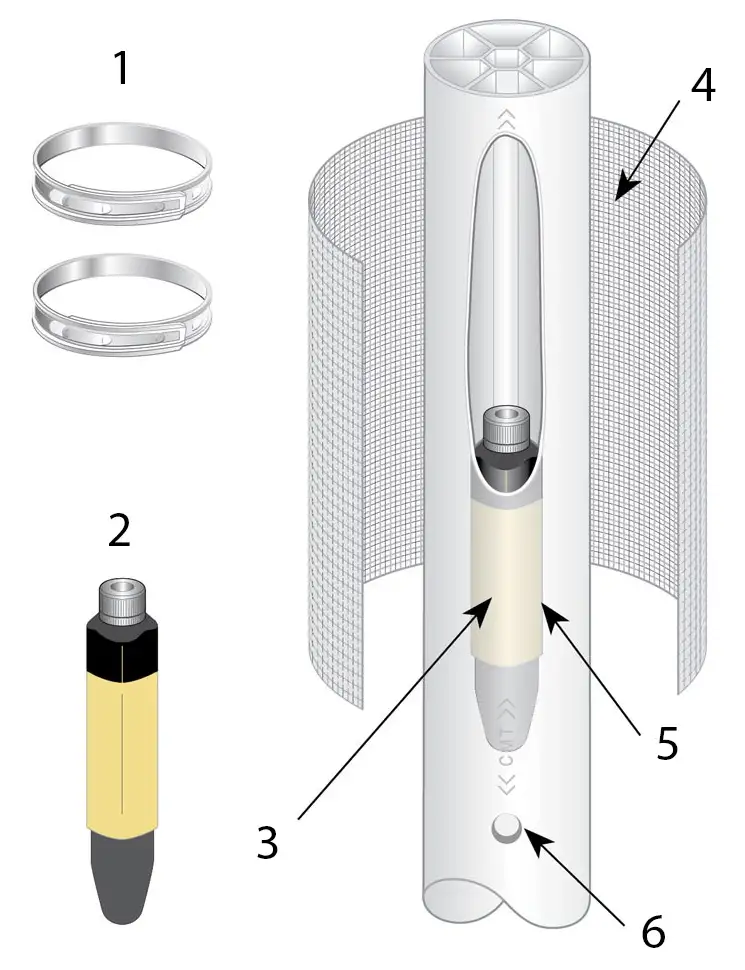

7-Channel Standard Port Assembly (106278):

- CMT Oetiker Clamps 41.0 LP

- Pie Plug for Base of Channel

- Channel Identifier

- CMT Screen 6″ 100 Mesh

- Pie Plug

- Vent Hole

Note:

Port plugs are tightened to a torque of 12.5 inch-pounds. Plugs in the base, or bottom, of the CMT should be torqued sequentially and incrementally to ensure even expansion.

Guide Point Port Assembly

Guide Point with Port Assembly

Part Number 105856

- Gear Clamp

Note:

Gear clamp is tightened to a torque of 12.5 inch-pounds, so guide point can support up to 20 lbs of additional weight (optional).

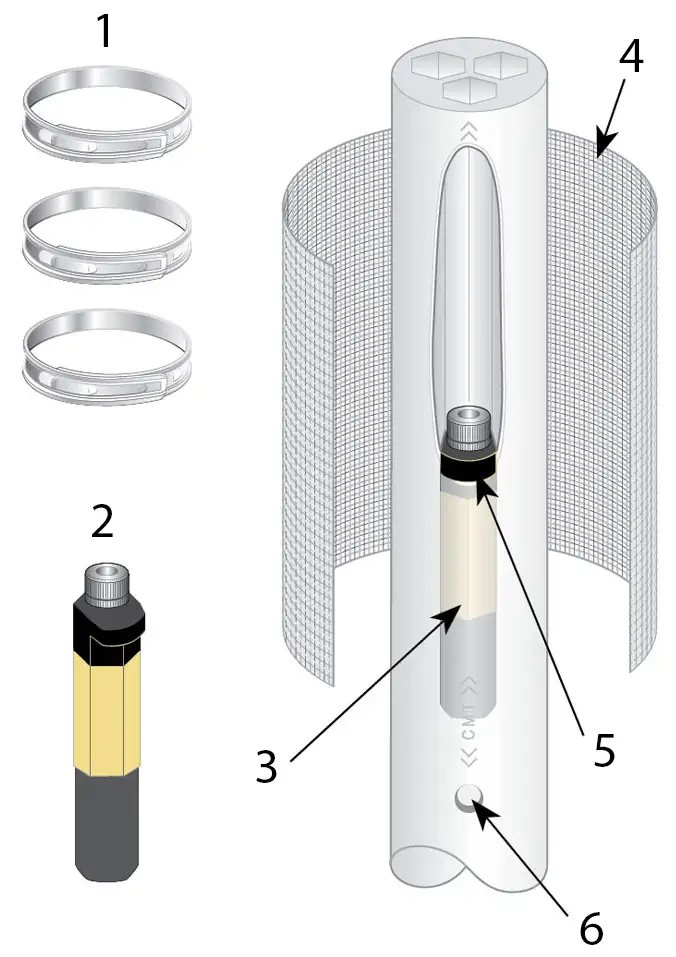

3-Channel Standard Port Assembly (107237):

- CMT Oetiker Clamps 28.0 LP

- Hex Plug for Base of Channel

- Channel Identifier

- CMT Screen 6″ 100 Mesh

- Hex Plug

- Vent Hole

Note:

Port plugs are tightened to a torque of 12.5 inch-pounds.

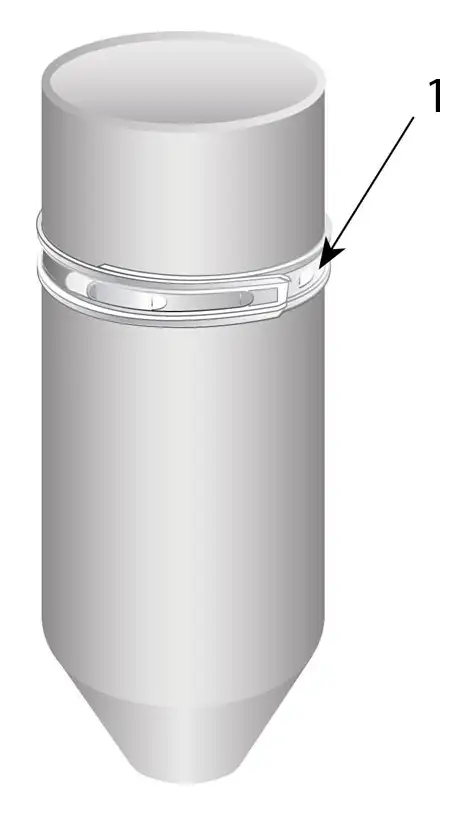

Guide Point

3-Channel Guide Point

Part Number 107178:

- CMT Oetiker Clamp 30.0 LP

Hand Tools for CMT Multilevel System Assembly

- Port Cutting Guide

(7 Channel Part Number 106850)

(3 Channel Part Number 107239) - 403 Sheet Metal Shears – 10″

Part Number 107983 - 403 Torque Tool Assembly – 12.5 in lbs

Part Number 107255 - 1/8″ Allen Wrench

(comes with Port Cutting Guide) - 403 Oetiker LP Pliers

Part Number 100177 - Hex Wrench

(comes with Port Cutting Guide)