High Resolution Multilevel Monitoring

Depth Discrete Groundwater Monitoring

Reduce Costs and Field Time

Solinst Technical Bulletin

High Quality Data

The benefits of using Multilevel Technologies have been proven time and time again on some of the most complicated, contaminated site investigations and cleanup projects in our industry. From projects involving nuclear waste sites, to landfills, petroleum spill sites and large MTBE plumes, multilevel technology continues to be an integral tool in the decision process. Understanding contaminant migration pathways, concentration gradients and having the defensible data required during intense litigation cases, are all in a normal days work for a multilevel groundwater monitoring system.

The Concept Is Simple

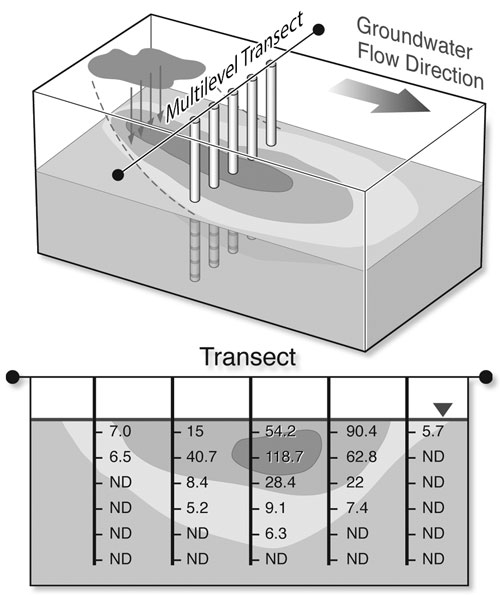

Within one borehole, the consulting firm has the option of installing and isolating several discrete monitoring zones. Both groundwater sampling pumps and pressure transducers can be dedicated right at the desired sampling interval. This enables the consulting firm to install transects of multilevel systems in the source zone and also near down gradient receptors. The data intelligence gathered during the use of multilevel monitoring systems, can be analyzed on both horizontal and vertical axies, which really paints a clear picture of what is happening below the surface. The data provides a solid indication as to how best to clean up the site. Detailed monitoring along property lines, near receptor wells etc, can be completed with confidence to prove the effectiveness of cleanup efforts. This provides a platform for continued improvement in the cleanup process.

Sampling from a Waterloo System

*Multilevels Provide Three Dimensional Groundwater Data

Cost Effective Monitoring

Multilevels provide many advantages that lead to cost savings, especially when compared to conventional monitoring wells. The Solinst Waterloo Multilevel System can monitor up to 24 discrete zones in a single borehole, while the less expensive CMT (Continuous Multilevel Tubing) System can monitor up to 7 zones in a single tube. In addition, CMT Systems can combine soil vapor monitoring in the same borehole as groundwater sampling.

Multilevel systems require fewer drilled holes. This results in lower drilling, installation and sediment disposal costs, along with reduced site disturbance. Using equipment such as a Solinst Tag Line to accurately and efficiently place sand and bentonite backfill layers can shorten installation times. The discrete interval that a multilevel port encompasses is small. This results in smaller purge volumes and more rapid responses to level changes, which decreases purge and sampling duration and the costs to dispose or contain purged water. CMT and Waterloo Multilevel Systems allow for simultaneous purging of channels, saving more time. With monitoring times reduced, there are further savings in field personnel time.

Down-hole Monitoring

While CMT and Waterloo Multilevel Systems support the use of portable or dedicated groundwater sampling pumps and support multipurge functionality, the Waterloo System has some key advantages that make it unique. Dedicated monitoring devices are available for use in the Waterloo Multilevel System. Permanent small diameter Double Valve or Bladder Pumps are ideal for high quality sampling, and Vibrating Wire Pressure Transducers can be installed for datalogging water level measurements.

Summary

Multilevel systems decrease long-term project costs, while increasing the amount of valuable data obtained. High resolution monitoring allows more detailed site characterizations and more accurate risk assessments. CMT and Waterloo Multilevel Systems provide defensible data, enabling increased confidence in decisionmaking. This data allows remediation strategies to be targeted more precisely, focusing efforts in the most effective and least expensive manner. Multilevel monitoring falls within the strategy of the Triad Approach for decision making, which includes Systematic Planning, Dynamic Work Strategies, and Real-Time Measurement.

*Illustration courtesy of LFR Levine-Fricke and the American Petroleum Institute