Waterloo Multilevel System Pre-Installation Requirements

Please complete this form to verify that proper consideration has been given to design and borehole specifications for each Waterloo Multilevel System to be installed.

1/ Minimum information required for effective design of the Waterloo Multilevel System:

Accurate borehole depth ________________

Borehole angle _____________________

Depth to which Waterloo System is to be installed _______________________

Borehole geology __________________

Drilling method ______________________

Casing size (minimum ID) _________________

Depth to base of well casing ______________________

*Borehole diameter (max and min) ________________________

Approximate depth to static water level ____________________

Expected pressure heads at each monitoring zone ___________

Number of monitoring zones ________________________

Desired port and packer locations/depths ___________________

Site conditions (e.g. dry field, bush, swamp, paved, etc.) ___________________________________________

Any special surface requirements for completion of installation (e.g. flush mounted, angled, etc) __________________________________________________

Monitoring equipment required __________________________________________________

(double valve pumps, bladder pumps, vibrating wire transducers, water level meters for open tubes, etc.)

*Note: Boreholes must be stable, circular, smooth and straight for best packer seal.

Using the layout of monitoring equipment at the proposed depth, Solinst can assist the client in determining the appropriate number of components to achieve your proposed monitoring scenario for the Waterloo Multilevel System. Final design and installation details remain the responsibility of the purchaser. Call for details about installation training.

2/ Ensure that these additional items are available on site during installation:

- Suitable and safe working area

- Clean water (~20 US gal (75 L)/100 ft. (30 m) installation)

- Compressed air or nitrogen to test pumps if installed

- Proper regulator for compressed air or nitrogen cylinder

- Pump Controller for testing pumps

- Readout unit to read Vibrating Wire Transducers

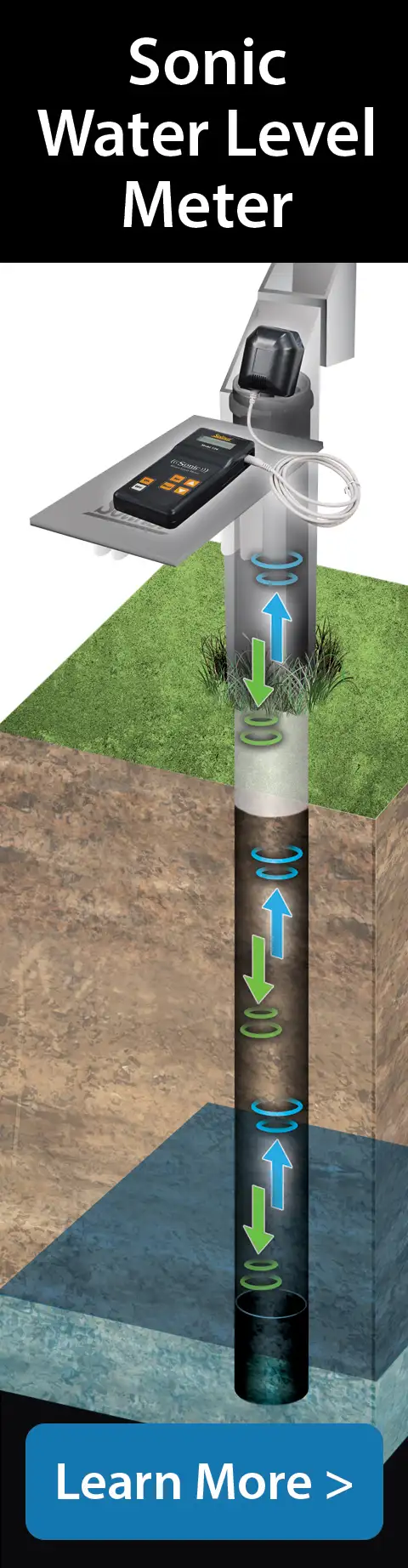

- Water Level Meter to check levels during installation

- Device to check total depth of borehole

- At least two client representatives for the installation

- Support device to assist in lowering Systems where depth to water is deeper than 100 ft. (30 m)