CMT Vapor Monitoring

Water Quality Probes

Solinst Eureka, a global leader in the design and manufacture of multiparameter water quality sondes.

Solinst Field Services

Safeguard your project’s success and mitigate any potential for downtime or additional costs.

Background

The vast majority of CMT applications are used for the sampling and monitoring of groundwater. However, CMT systems can also be used to sample contaminant vapor concentrations in the unsaturated or vadose zone above the water table.

Not all contaminants produce significant vapor to make vadose zone monitoring worthwhile. Appropriate contaminants are those characterized by high vapor pressures and include components of gasoline (eg BTEX); chlorinated solvents such as trichloroethylene (eg TCE) and their breakdown products (eg vinyl chloride and methane). These vapors can be hazardous due to their potential to explode, as in the case of BTEX and methane, or due to their general toxicity when inhaled (vinyl chloride, benzene).

Depth-discrete vapor sampling is also necessary to accurately assess the potential risks to above-ground receptors resulting from vapor migration. Such assessments are now an essential component of environmental investigations performed at contaminated sites undergoing redevelopment (i.e., Brownfield sites).

CMT System

The CMT system can be easily modified to accommodate vapor monitoring in one or more channels. For example, the system could be configured so that some of the channels sample vapor from the vadose zone; or all of the channels can be dedicated to soil vapor monitoring.

During vapor sampling, the CMT is constructed in the same manner as for groundwater sampling, except that each vapor sampling channel is fitted with a special flow through seal assembly which is inserted at the top of the channel.

Vapor Wellhead

Assembly Model 403

A channel seal assembly allows attachment of a three-way valve to direct vapor to a pressure gauge connected at one end of the valve and a sample vessel at the other.

Images courtesy of Waterra (UK) Limited

Data courtesy of Paul Sojka, Pollution Control Manager, Worcestershire County Council, UK

Vapor Sampling Considerations

Vapors have the potential to diffuse rapidly through some materials including polyethylene from which the CMT is constructed. In order to limit the adverse effects of diffusion through the outer CMT channel wall or the inner chambers it is recommended that a protocol be developed that ensures a representative sample is obtained directly from the port intake area.

It is very important to thoroughly purge any gas present in the channel of the system, followed by field screening of vapor concentrations until readings stabilize. Sampling should immediately follow after purging and stabilization. It is also advisable to maintain a steady flow of vapor through the system and draw a sample without stopping the flow, to minimize any sample bias attributable to diffusion through the tubing walls.

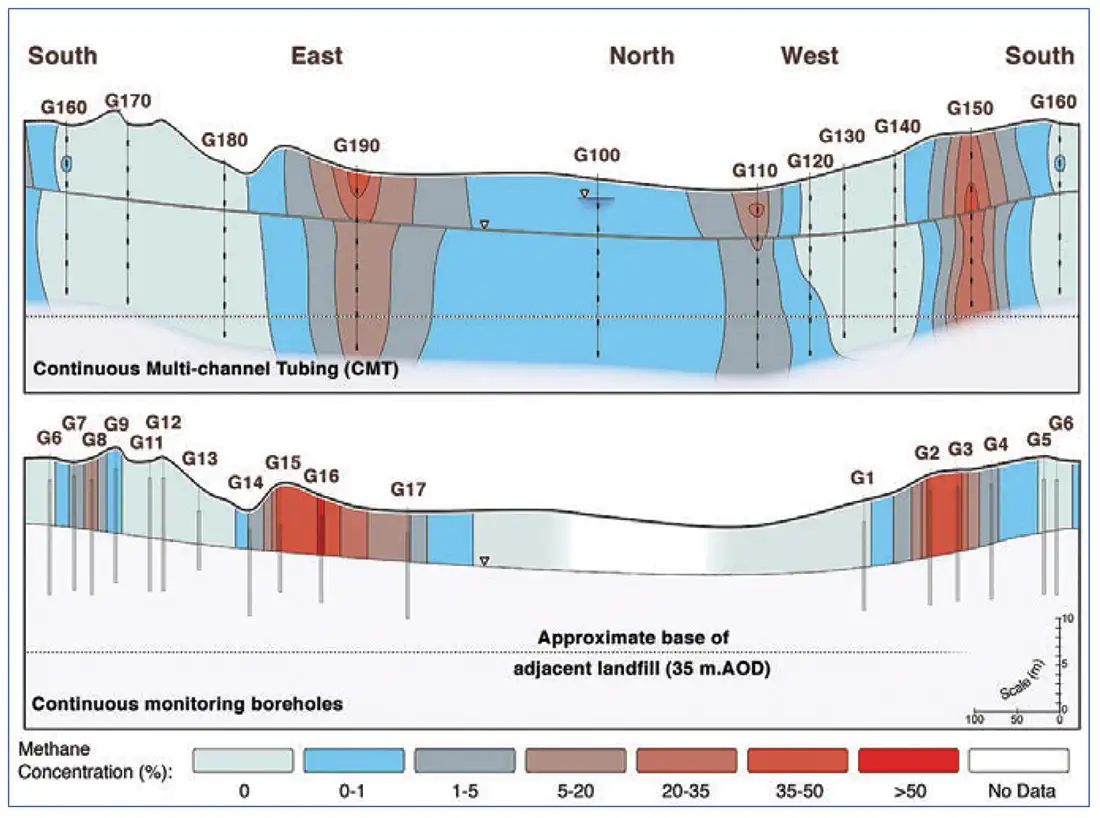

Concentrations of methane in both the vapor phase and dissolved phase collected from CMT systems are shown in the upper diagram. The lower diagram plots methane vapor concentrations taken from long screened wells.

Reference: Electrical Power Research Institute (EPRI), 2005. Reference Handbood for Site-Specific Assessment of Subsurface Vapor Intrusion to Indoor Air. Document#1008492. Published by EPRI, California.