Cutting Outer Ports and Vent Holes

Water Quality Probes

Solinst Eureka, a global leader in the design and manufacture of multiparameter water quality sondes.

Solinst Field Services

Safeguard your project’s success and mitigate any potential for downtime or additional costs.

Step 8) Install the Port Cutting Guide

Slide the Port Cutting Guide over the CMT tubing down to Port 1. Align the notch stamped “1 ” on the Port Cutting Guide with the line you drew along the Channel 1 identifier. Position the Port Cutting Guide so that the depth mark “+” (indicating the centre of the Port) is visible in the window in the center of the Port Cutting Guide (Figure 8). Secure the Port Cutting Guide to the CMT tubing by tightening the knurled Locking Bolts on the underside of the guide (Figure 9). Tighten the bolts, by hand only, to prevent the Port Cutting Guide from moving.

Figure 8 – CMT Port Cutting Guide

Note:

When using the Port Cutting Guide, ensure that the cutting bolts are located below the number 1 on the front of the Guide. The locking bolts go below the number 4 on the back of the Port Cutting Guide.

Figure 9 – 7-Channel CMT Port Cutting Guide with Plugs

Step 9) Use Cutting Bolts to Cut Holes

Next, cut three holes, as described below into Channel 1 using the cutting bolts screwed into the Port Cutting Guide. Do not rush when screwing the cutting bolts into the Port Cutting Guide. Ensure the bolts are properly lined up with the holes in the Port Cutting Guide so that cross threading does not occur.

Note:

Do not rush when screwing the cutting bolts into the Port Cutting Guide. Ensure the bolts are properly lined up with the holes in the Port Cutting Guide so that cross threading does not occur.

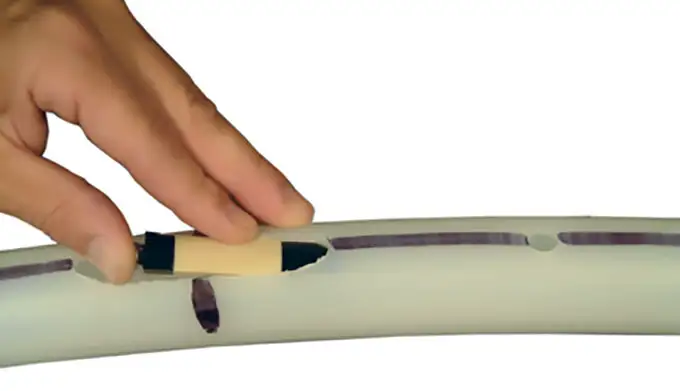

Start by threading a cutting bolt into one of the holes located on the same side as the window. Use the hex wrench to tighten the Cutting Bolt. Tighten the bolt a few revolutions, then loosen it one revolution. Continue doing this until the Cutting Bolt “bottoms out” (Figure 10). Remove the Cutting Bolt. There should be a plastic disk inside of the cutting bolt. If there isn’t, re-insert the cutting bolt and repeat the cutting process (make sure that the knurled Locking Bolts are tight). Push out the piece of plastic from the inside of the Cutting Bolt by inserting an Allen wrench through the small hole drilled in the head of the Cutting Bolt (Figure 11 ). Repeat this process to cut all three holes. The two upper holes will provide the port plug access and the lowest hole is the vent hole (Figure 12).

Note:

For easy effective cutting, advance the cutter bolt in alternating increments of ~1.5 turns clockwise, and then 0.5 turn counter-clockwise, repeatedly.

Figure 10 – CMT Port Cutting Guide – Cutting Out Sampling Port Hole

Figure 11 – CMT Removing LDPE Cutting Plug

Figure 12 – CMT Tubing Port Cutting Setup

Note:

If installing numerous systems, spare cutting bolts can be ordered, as they may become dull after repeated use. It is recommended to order an extra bolt per 10 ports constructed.

Step 10) Cut Panel Between Upper Two Port Holes

Loosen the cutting tool and move it “down” the CMT and out of the way. Next, use the snips as shown in Figure 13 to cut out the panel of plastic between the upper two port holes. Do this carefully and keep the snips parallel to the channel side wall to avoid cutting into the walls separating Channel 1 from Channels 2 and 6. Make the opening as large as possible to facilitate the insertion of the expansion plug as described in the next step.

Note:

The two upper holes allow you to use snips to cut away a panel of plastic between the two holes, creating a 3-inch long port in Channel 1. The bottom hole is a vent hole. A vent hole is needed to allow air to escape from the channel beneath the monitoring port when the CMT tubing is inserted into the waterfilled borehole during well installation.

Figure 13 – CMT Port Cutting

Figure 14

Figure 15

Standard Port Assembly (#106278)

Step 11) Insert Expansion Plug

Insert an expansion plug through the opening (Figure 16) so that it seals Channel 1 below the monitoring port and above the vent hole. If necessary, use the torque driver to gently push the plug into place (Figure 17). Use the snips to trim the port opening if you have difficulty inserting the plug. Tighten the plug to a torque of 12.5 inch-pounds using the supplied torque driver.

Note:

The vent hole does not allow cross connection with other monitoring zones because the bottom of the channel is sealed with a water-tight plug.

Figure 16 – Insert CMT Pie Plug into Sampling Port

Figure 17 – Insert Solinst CMT Multilevel System Pie Plug into Sampling Port

Note:

When installing the expansion plug, temperature of the CMT should be between -15ºC and 35ºC. If air temperature is above 35ºC, use cold water to cool down the tubing at the port before installing the expansion plug.

Step 12) Install the Well Screen

The last step in making the Channel 1 port consists of wrapping the stainless steel mesh around the port, forming a well screen over the opening. Center the mesh over the port opening and wrap it tightly around the CMT tubing (Figure 18). Use the low profile Oetiker clamps and pliers to firmly secure the mesh to the tubing. See the section below for more details about installing Oetiker clamps. Use two clamps for each monitoring port (Figure 20). Construction of Port 1 is now finished. You are now ready to make Port number 2.

Note:

Wetting the Oetiker Clamp reduces friction, making installation easier.

Installing Oetiker Clamps

Wrap the Oetiker clamp around the part (eg. screen, centralizer, guide point) you are clamping. Allow the first (closest) retaining hook to pass through the long slot opening. Squeeze the clamp by hand until the retaining hook catches the end of this opening. Figure 19 shows this step. Fit the ‘jaw tips’ of the Oetiker pliers into each of the clamp’s ‘tunnels’. Squeezing/closing the Oetiker pliers simultaneously draws the two tunnels together. With the two tunnels drawn together, push down on the tail of the clamp, so that the furthest retaining hook passes through the last slot. Now release the pliers so that the retaining hook catches the clamp and holds.

Figure 18 – Wrapping Stainless Steel Mesh around CMT Sampling Port

Figure 19 – Affixing CMT Oetiker Clamp Over Sampling Screen

Figure 20 – Tightening Oetiker Clamp over CMT Stainless Steel Mesh for Sampling Port

Step 13) Line-up Port Cutting Guide

Slide the Port Cutting Guide down to Port 2. Position the Port Cutting Guide exactly as you did for Port 1. The depth mark should be visible in the window of the Port Cutting Guide and the longitudinal Channel 1 identifier should be indexed to the number “1” stamped on the guide (Figure 21). Now, rotate the Port Cutting Guide (without moving its position along the CMT tubing) so that the longitudinal line is now indexed to the number “2” stamped on the guide (Figure 22). This positions the Port Cutting Guide so that the cutting bolts will cut holes only into Channel 2. Secure the Port Cutting Guide using the knurled Locking Bolts as before. Cut the two port holes and one vent hole into Channel 2. Next, loosen the cutting tool and slide it down the tubing out of the way.

Note:

To avoid installing ports in the wrong channels start by positioning the Port Cutting Guide so that the depth mark is visible in the window, then rotate the guide so that the appropriate number (corresponding to the port number) is indexed against the line you drew earlier along the longitudinal Channel 1 identifier. This step is very important

Figure 21 – Aligning CMT Port Cutting Guide to correct Sampling Depth

Figure 22 – Aligning CMT Port Cutting Guide to the

correct CMT Tubing Channel Using the Numbers allocated at the top

Note:

At some sites, you may decide that it is not necessary to monitor every channel. In that case, only cut ports in the desired channels.

When constructing the bottom assembly, only insert the expandable plugs into the monitored channels, leaving the other channels open so that they can fill with water as the CMT tubing is inserted into the borehole (e.g. If only three channels are monitored, only those channels should have plugs inserted at the base.) This reduces buoyancy during well installation.

Step 14) Create Port 2 Opening

Snip away the panel of plastic between the upper two holes, creating an opening for Port 2.

Step 15) Finish Constructing Port 2

Next, insert an expansion plug through the opening, positioning it below the monitoring port, and tighten it to 10 inch-pounds as before. Finally, wrap a piece of stainless steel mesh around the opening and secure it with two stainless steel clamps. You have now finished constructing Port 2.

Step 16) Construct Ports 3 to 6

Continue the steps described above for Ports 3 through 6.