Preparation

Water Quality Probes

Solinst Eureka, a global leader in the design and manufacture of multiparameter water quality sondes.

Solinst Field Services

Safeguard your project’s success and mitigate any potential for downtime or additional costs.

Before making any ports in the CMT tubing, make a sketch of the desired well design. Show the depths of the desired monitoring zones and centralizers (if used) in feet/meters below ground surface. Also, show the depths of the desired lifts of sand and bentonite graphically on the figure. This will come in handy when you are measuring the depths of the backfill materials when you are building the well. If you are building a CMT Multilevel System well where alternating layers of sand and bentonite backfill are added from the surface, try to allow for two feet or more of sand above and below the monitoring ports to ensure that the bentonite does not cover the monitoring ports.

Note:

Avoid using “single lifts” of grout greater than 50 ft in the unsaturated zone.

Remember to allow sufficient wellhead access when you install the protective cover over the well. Plan on using a large well cover (greater than 4″ diameter is recommended) to allow plenty of room to access the wellhead. A diagram showing suggested dimensions of the wellhead and protective cover is shown in Figure 2 for flushmount and above ground completions.

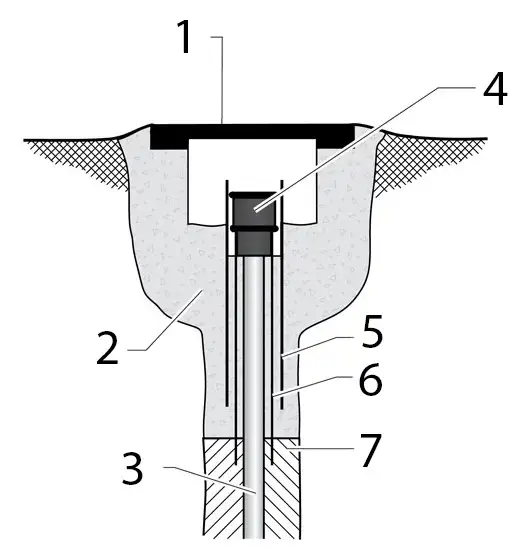

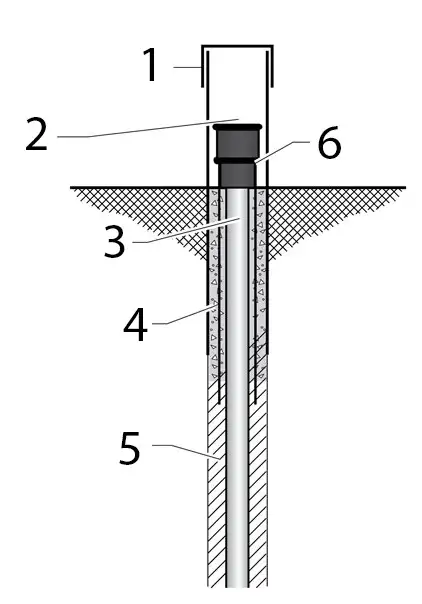

Figure 2 – CMT Wellhead Completion Examples

Flushmount CMT Wellhead Completion Example

- Flushmount Well

Cover Minimum

4″ dia. (10cm)

with 7″ dia. (18cm)

Useable Space - Concrete

- CMT Tubing

- Solinst CMT Wellhead

- Locking Plug

- 2″ Schedule 40 PVC

- Bentonite

CMT Wellhead Completion Example

- Lockable Well Cap

- Solinst CMT Wellhead

- CMT Tubing

- Concrete

- Bentonite

- 2″ Schedule 40 PVC