Water Flute System Installation

Depth Discrete Groundwater Monitoring

Reduce Costs and Field Time

Water Flute System Installation

The Water Flute multilevel groundwater system is typically installed in open bedrock wells via eversion, in a similar process as a blank liner installation (see Flute Flexible Liners).

The Water Flute can also be installed in the overburden using multi-screened cased holes.

The installation of a Water Flute is affected by the depth and diameter of the hole, the relative transmissivity of the hole, the depth to the water table, and the rate at which water can be supplied to fill the liner.

If the hole is too tight to allow the liner to push the water into the formation, the water can be pumped from beneath the liner using a pump tube emplaced in the hole before the liner installation. After installation, the pump tube is removed in order to create a continuous seal.

The system can be used for artesian situations with a permanent grout seal.

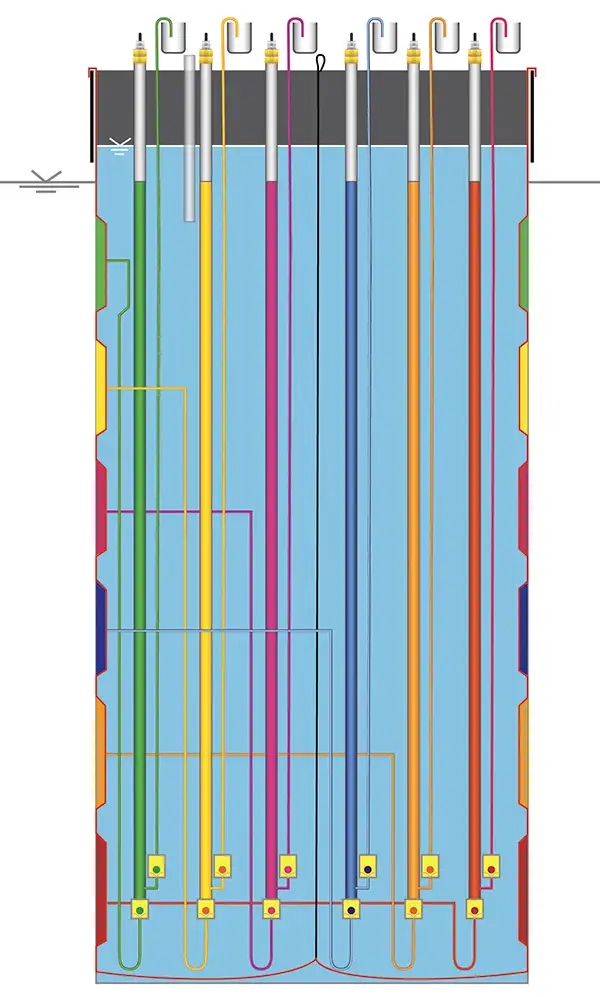

Due to the size of the large tubing and pumping hardware components of the system, the pumping system is fully sheathed, connected to the liner, and lowered down the hole as the liner continues to evert.

Water Flute Well Completion

There is no need for an exterior seal with grout, sand or bentonite. The liner seals the entire hole and the water is drawn directly from the formation. A Solinst Flute Locking Wellhead Cover can be used as a security feature for stickup completions.

Solinst Flute Locking

Wellhead Cover

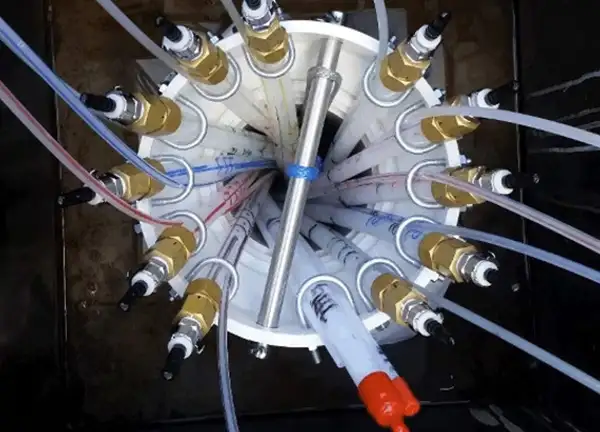

Water Flute Pump System with Six Sampling Ports

(for an understanding of system components only)

Number of Monitoring Zones Per Hole

The maximum number of monitoring zones for Water Flute system is determined by the diameter of the borehole. The typical number of ports that can be installed in a liner are 6, 10, 15, and 20 in hole diameters of 4″, 5″, 6″, and 8″ respectively.